Contact Fax

0552-4070672

PRODUCTS

Introduction

2.6. Dimensions: length × width × height =210 mm×105 mm×75mm; U-shaped opening size: standard 40mm, customizable.

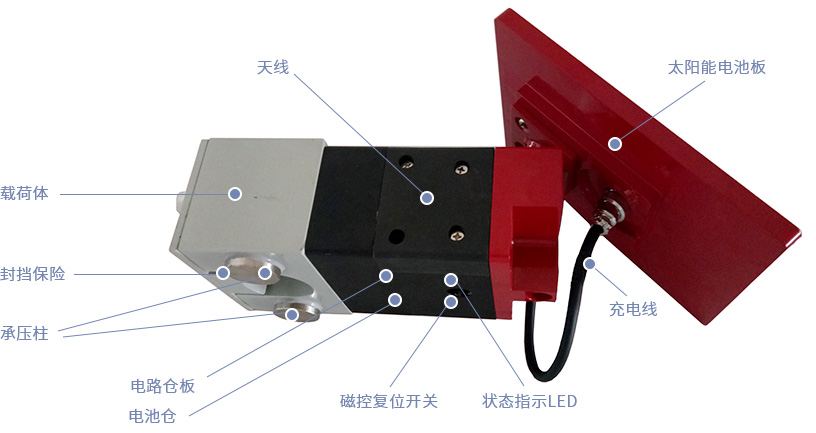

图2. SM35AWS-FL遥测式示功仪功能部件指示图

4.1 LED status indicator description

|

State of the LED |

statements |

Sensor status |

Notes |

|

red(Working mode, status, ZigBee communication) |

Blink 3 times at an interval of 0.4s |

reset |

Indication after repowering on or successfully resetting by magnetic reset switch (magnetic steel near "reset" indicating position 3s). |

|

Long light 2 to 20 seconds |

Joining the ZigBee network |

Add ZigBee network operation instructions after the sensor is powered on or reset for the first time. |

|

|

Turn on for more than 20 seconds until exit |

The configuration mode is successfully entered. Procedure |

Common parameters, instrument calibration, power diagram control parameters, acquisition cycle configuration. |

|

|

Blink at 1s interval |

Active state |

|

|

|

Blink 3 times at an interval of 0.4s, repeat at an interval of 1s |

Owe the battery |

The battery is low. |

|

|

green(Power diagram measurement, LoRa Communication) |

Long bright |

In the work diagram measurement |

Continue the process for at least one cycle of stroke |

|

Blink at 1s interval |

Send regular sequence

|

When LoRa (memory) is successfully added to the network, the normal sequence is sent. Every time the sequence is sent, the base station needs to wait for the reply. There is no reply after 30 seconds, and the sequence is resend. |

|

|

Sends power diagram packets |

After the power map measurement is completed and LoRa (memory) is successfully added to the network, the transmission power map data packet is divided into multiple packets. The data transmission of each packet needs to be confirmed by the base station, otherwise it will be re-transmitted. The whole process will last about 30 minutes depending on the network communication situation. |

4.2

1) Configure well name and site configuration (establish local wireless data communication network with RTU); Note: For ZigBee wireless communication mode only.

Related Applications

Contact Fax: 0552-4070672

Website: www.sunmoon-china.com

Mailbox: sales@sunmoon-china.com

Add: Sun Moon Science and Technology Park, No. 985, Xingzhong Road, High-tech Zone, Bengbu, Anhui, China

About Us

Company Profile

Corporate History

Honor

Company Culture

Photo Gallery

Products

Force measurement and load cell

Wireless digital sensor

Temperature and pressure sensor

Angle, displacement, speed sensor

Oilfield measurement and control systemWeighing control system

Solution

Weighing logistics network solutions

Construction machinery sensor solutions

Oil and gas IoT solutions

Follow Us

Copyright © 2020 Bengbu Riyue Instrument Research Institute Co., Ltd. 皖ICP备19017385号-1 Powered by: www.300.cn