Contact Fax

0552-4070672

PRODUCTS

The characteristics of

Industrial temperature test, has been widely used in major oil and gas and other industrial temperature testing field;

Explosion-proof design: the flame-proof aluminum shell, intrinsically safe circuit board system;

Protection grade: IP67, fully sealed waterproof design;

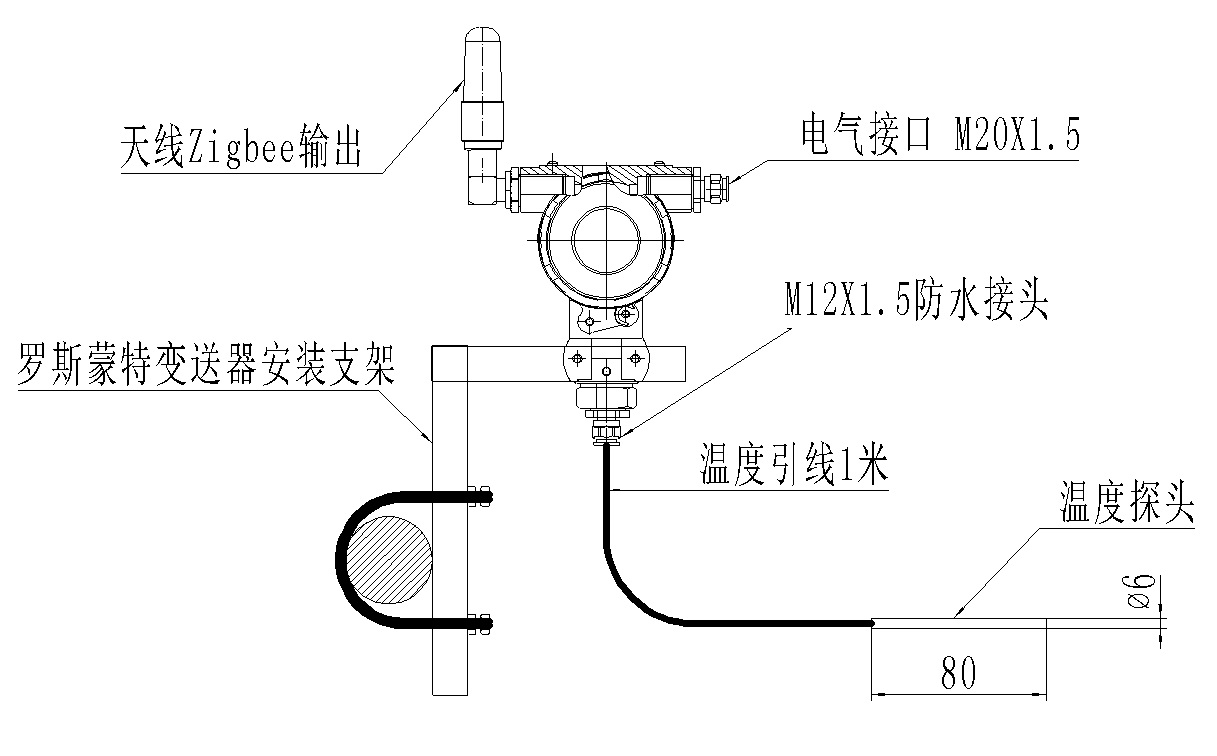

Zigbee communication network to the coordinator or a router to its configuration and test;

Four and a half LCD display: temperature data, battery voltage;

LED indicator: reset instructions, directions configuration mode, access instructions, data acquisition;

Installation direction adjustable: by bringing union (or joint) installed on the protective casing, the adjustable direction.

Insert depth adjustable: by bringing the joint adjust temperature probe length, namely the insertion depth adjustment.

2. Performance indicators

21. The technical indexes

Working conditions: temperature, and 40 ℃ or less Tamb + 65 ℃ or less; The atmospheric pressure: 80 kpa to 110 kpa. Humidity, 5% RH to 95% RH

Power supply: 3.6 V19Ah batteries

Level of accuracy: 0.2 ℃ and 0.1 ℃

Sensor element: RTD Pt100

The output signal: Zigbee

Protection grade: IP67

Case material: cast aluminum

Protection casing material: 304 316 LSS

The process connection: union with protective casing

Range: - 200 ~ 600 ℃ range can be customized

Weight: 1 kg

Dimension: 390 * 116 * 137 (customizable)

F8913 module factory default name: well network ID: 123456, 58418: the default physical channel 13

XBEE module factory default network ID: 21 default communication channel: the default encryption enabled: 0

2. Explosion-proof authentication parameters

Explosion-proof number: CE18.2230 X

Explosion-proof marks: Ex ib Ⅱ C T4 Gb

Rated voltage: 3.6 V + / - 1% rated current: 50 ma rated power: 0.18 W

Directions for use

5.1. All transmitter through digital calibration, the different between the transmitter has the complete consistency and interchangeability.

5.2. In transit, all of the transmitter battery is in the off state, temperature transmitter installation on site, need to unscrew header back cover, battery access. Attention should be paid to tighten sheath to prevent leakage.

Install temperature transmitter (1) 5.3. The line pipe, pressure, discharge empty running. A blind than the sensor probe in the line pipe sleeve diameter is a little bigger (phi) 24 hole; (2) insert the tube sets of vertical from opening to half of the pipe diameter, and then along the hole week seal welding on the pipe; (3) blind pipe set inside into the heat conduction oil, about 2/5 of the volume of; (4) temperature sensor probe into blind pipe sleeve, adjust good header direction, with wrench will union tighten, pipeline transport.

5.4. Under the condition of temperature transmitter for a long time not to use, please open the header back cover, battery power.

6. Matters needing attention

6.1. This product use battery model have examined the explosion-proof certification, battery model for ER34615H; Replace the battery, it is prohibited to use other model battery.

6.2. Product antenna casing for the plastic material, potentially dangerous electrostatic charge! Use should be avoided in the friction! Please use wet cloth to wipe clean!

Related Applications

Contact Fax: 0552-4070672

Website: www.sunmoon-china.com

Mailbox: sales@sunmoon-china.com

Add: Sun Moon Science and Technology Park, No. 985, Xingzhong Road, High-tech Zone, Bengbu, Anhui, China

About Us

Company Profile

Corporate History

Honor

Company Culture

Photo Gallery

Products

Force measurement and load cell

Wireless digital sensor

Temperature and pressure sensor

Angle, displacement, speed sensor

Oilfield measurement and control systemWeighing control system

Solution

Weighing logistics network solutions

Construction machinery sensor solutions

Oil and gas IoT solutions

Follow Us

Copyright © 2020 Bengbu Riyue Instrument Research Institute Co., Ltd. 皖ICP备19017385号-1 Powered by: www.300.cn