Products

PRODUCT CENTER

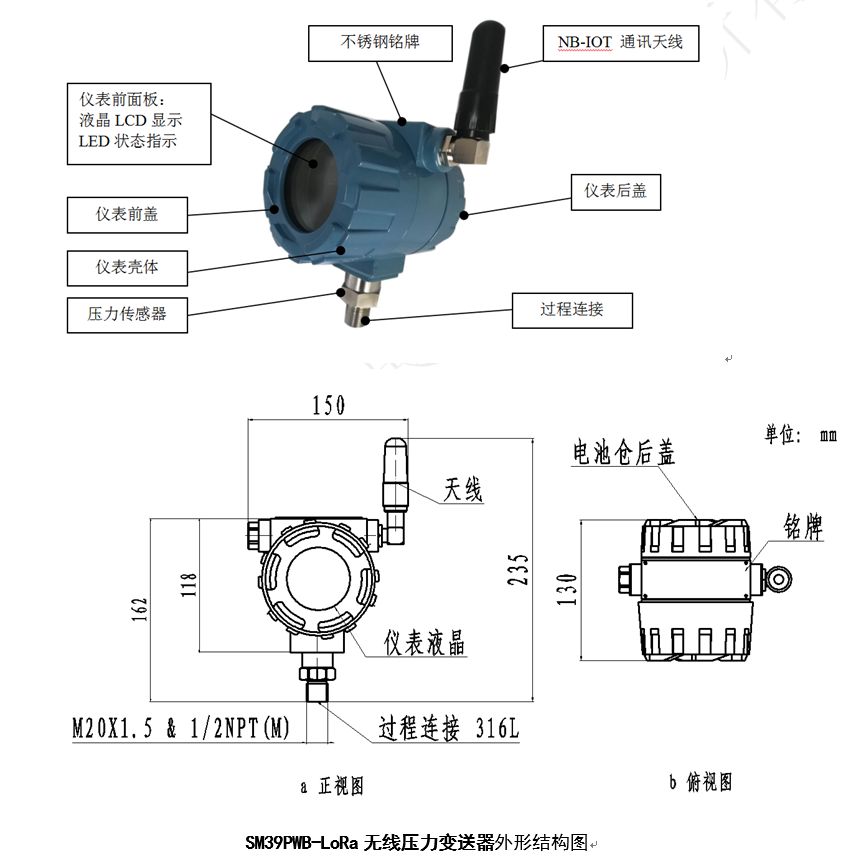

LoRa Wireless Pressure Transmitter SM39PWB

1. Features

- Embedded wireless data transmission module based on LoRa spread spectrum technology, using LoRa network to provide users with wireless data transmission function

- Oilfield oil pipeline pressure, on/off well formation pressure, pressure monitoring and upper/lower limit alarm;

- Explosion-proof design: explosion-proof aluminum shell, intrinsically safe circuit board system;

- Protection level: IP68, fully sealed waterproof design;

- The instrument can set alarm enable, upper and lower limits, delay, dead zone, maximum range, minimum range, decimal places, upload frequency, acquisition frequency, change amount alarm, and other parameters.

- LED Indication: reset indication, configuration mode indication, networking indication, data acquisition indication;

- 4 1.5-inch LCD display: pressure data, battery capacity icon, upper and lower limit alarm, and other parameters.

- Adjustable installation direction: can be adjusted through a live connection or adapter to connect to the on-site pipeline valve.

- This product has been widely used in the oil and gas Internet of Things industry.

2. Performance Indicators

- Operating ambient temperature, -40~70℃,

- Ambient humidity: 0~95%RH, no condensation;

- Protection level: IP68;

- Explosion-proof mark: Ex ib II C T4 Gb,Explosion-proof certificate: CE18.2230X;

- Power supply: ER34615 lithium thionyl chloride battery (implementation standard: SJ52278/1), two primary batteries in parallel, capacity 3.6V 38Ah; battery connector SM-2P (female head: pin 1 positive, pin 2 negative) connected to the instrument; power supply voltage range, 3.0V~3.6VDC;

- Battery continuous working time: ≥1 year (pressure acquisition frequency 1 time/min, communication frequency 1 time/h);

- Battery replacement method: open the instrument back cover and quickly replace it through the standard SM-2P interface;

- Long-term stability: drift, ±0.1%FS/year;

- Measurement performance: range, 0 ~2.5MPa、0~6.0MPa、0~25MPa、0~40MPa、0~60MPa、; accuracy, 0.5%F.S; can be customized according to actual needs; Complies with GB/T 28474.1 and GB/T 28474.2 regulations;

- Pressure sensor: using piezoresistive core, pressure overload capacity, 150%FS;

- Process connection interface: M20X1.5 or 1/2''NPT, can be customized according to actual needs ;

- Communication method: LoRa Multiple frequency bands (433/470/780/868/915MHz) ;

- Communication theoretical bandwidth: 6 levels adjustable (0.3, 0.6, 1.0, 1.8, 3.1, 5.5 Kbps)

- Online debugging and setting function: it can be debugged and set through computer + wireless receiver without uninstalling during online installation; the setting data content includes:

- Communication working parameters: network number, air rate;

- Measurement working parameters: alarm enable, upper and lower limits, delay, dead zone, maximum range, minimum range, decimal places, upload frequency, acquisition frequency, change amount alarm;

After the instrument is powered off, the setting data is retained;

- Online upgrade: it can be realized through the configuration serial port and computer operation without uninstalling during installation;

- Liquid crystal (LCD) display: LCD display area, length × width = 45 × 35mm, the background color is green, the display content includes real-time measured value, pressure unit, instrument range, battery power, voltage, signal strength; the decimal point of the real-time measured value can be set, and the default is to retain 2 decimal places after the decimal point;

17. Instrument shell: the material is aluminum alloy, the shell sealing ring (gasket) is silicone rubber, and Vaseline is applied to the front and rear cover threads; the dial diameter is 60mm, and the appearance color number is RAL5007;

18. Dimensions: length × width × height = 150 × 130 × 235mm (MAX).

19. Sampling interval: The acquisition interval is 1~60 minutes, which can be set.

20. Sending interval: 5~1440 minutes can be set.

21. SMS sending interval: 5~1440 minutes can be set.

Explosion-proof certification parameters

Explosion-proof certificate number : CE18.2230X

Explosion-proof mark: Ex ib ⅡC T4 Gb

- Appearance structure and function introduction

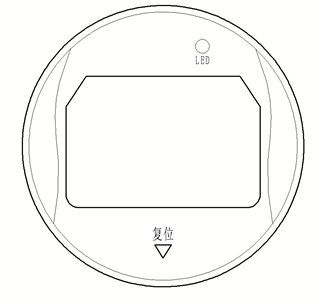

SM39PWB-LoRa Wireless pressure transmitter Front panel function diagram

Front panel LED: red indicates temperature acquisition status and sleep to wake-up status,

-

Front panel reset: through a magnet, below the front cover of the shell, the magnet points upwards to the reset arrow, and is kept stable for 3-5 seconds before removing the magnet. The red LED flashes three times, and the LCD display 8888 also flashes three times synchronously, indicating that the instrument has been successfully reset. The main purpose of the reset is to enter the instrument to modify the internal parameters, or to refresh the current pressure value, and to re-establish the network connection.

5. On-site installation and use instructions

5.1. All transmitters have been digitally calibrated, and different transmitters have complete consistency and interchangeability;

5.2. During transport, all transmitter batteries are in the disconnected state. When installing the pressure transmitter on site, it is necessary to unscrew the head cover, turn on the battery switch, and pay attention to tightening the sheath to prevent water leakage.

5.3. For pipelines and permanently shut-in wells, install the honeycomb network wireless pressure transmitter. First, close the valve (needle valve or gate valve) on the pipeline where the pressure transmitter is to be installed. There are two installation methods: (1) Screw the pressure transmitter directly into the upper port of the needle valve; (2) Screw the live connection or adapter into the upper port of the needle valve, and then screw the transmitter into the upper port of the live connection or adapter. This installation method uses a live connection or adapter to adjust the direction. After installation, open the needle valve to confirm that there is no leakage, indicating that the installation is qualified.

5.4. After installing this honeycomb network wireless pressure transmitter, network parameters can be set via buttons or debugging tools.

5.5. If the transmitter is not used for a long time, the pressure transmitter can be set to sleep mode through the debugging tool (during the factory entry and warehousing process, it is uniformly set to sleep mode or off state; on-site parameter adjustment and activation are required for normal use. ). The online list of the debugging software interface is shown below:

6. Precautions

6.1. The battery model used in this product is ER34615H-3.6V38Ah; the use of other battery models is prohibited.

6.2. The product antenna housing is made of plastic and has a potential electrostatic charge hazard! Avoid friction during use! Please wipe with a damp cloth when cleaning!

Keywords:

Related Applications

undefined

Language

Language