Products

PRODUCT CENTER

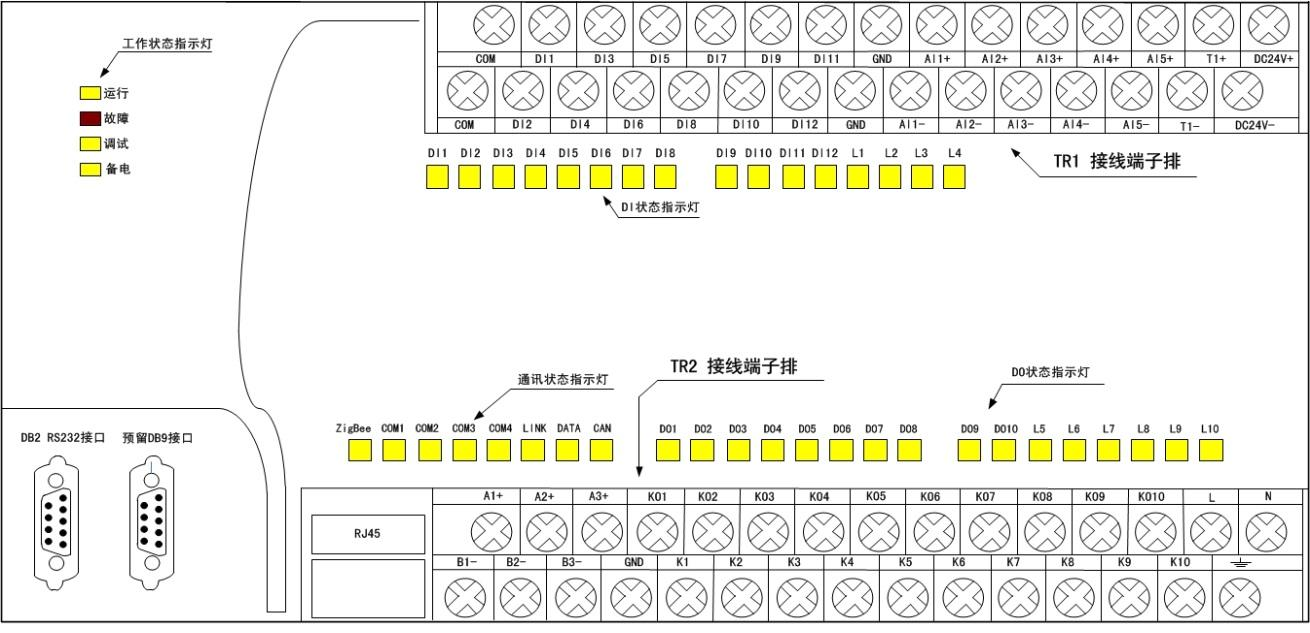

RTU intelligent remote monitoring and control terminal SM40P-5800

Category:

1. Overview

2. Appearance Diagram

3. Technical Parameters:

|

Item |

Description |

|

Processor |

32 Bit microprocessor, main frequency 450MHz

|

|

Running Memory |

128 MB, Power-off Data Preservation |

|

FLASH Memory |

256MB |

|

Power Supply |

AC 180 V ~ 265V |

|

Backup Power Supply |

DC 24V |

|

6 Analog Input Channels ( AI ) |

|

|

12 Digital Input Channels ( DI ) |

Passive dry node, internal device power supply 24V |

|

10 Digital Output Channels ( DO ) |

Relay output, capacity 5A/250VAC,5A/30VDC |

|

3 Channels RS485 |

Modbus RTU Master Protocol |

|

1 Channels RS232 |

Modbus RTU slave Protocol |

|

1 Ethernet Channels RJ45 |

Modbus TCP or IEC60870-5-104 Protocol |

|

1 Channels 2.4G ZigBee Communication Interface |

ZigBee PRO 2007 Standard, or built-in WIFI function, can be debugged through APP (this function is optional, please specify when ordering) |

|

Watchdog, Real-time Calendar Clock |

Calendar clock power-off time preservation 3 Months |

|

Operating Temperature |

-40 ℃~ +70 ℃ |

|

Storage Temperature |

-55 ℃~ +85 ℃ |

|

Relative Humidity |

5% ~ 95% No condensation |

|

Weight |

0.48Kg |

Keywords:

RTU

Previous

Related Applications

undefined

Language

Language