Products

PRODUCT CENTER

Zigbee wireless pressure transmitter (small housing) SM39PWB

1. Features

- Pipeline pressure testing, widely used in major oil and gas fields and other industrial pressure testing fields nationwide;

- Explosion-proof design: explosion-proof aluminum shell, intrinsically safe circuit board system;

- Protection level: IP67, fully sealed waterproof design;

- Zigbee Communication, configurable and testable as a coordinator or router in the network;

- 4 1/2 LCD display: pressure data, battery voltage;

- LED Indication: reset indication, configuration mode indication, networking indication, data acquisition indication;

- Adjustable installation direction: can be adjusted via a union or adapter connected to the on-site pipeline valve.

2. Performance Indicators

21. Technical Specifications

- Operating environment: temperature, -40℃≤Tamb≤+65℃; atmospheric pressure: 80KPa~110kPa; humidity, 5%RH~95%RH

- Power supply: 3.6V battery power

- Accuracy grade: 0.5, 0.25, 0.1, 0.075

- Measurement principle: piezoresistive

- Output signal: ZIGBEE

- Protection level: IP67

- Housing material: cast aluminum

- Contact medium material: 316LSS, 304

- Process connection: 1/2″NPT(M) ,M20*1.5,R1/2

- Range: 0~ 110 Mpa (range optional)

- Weight: 1kg

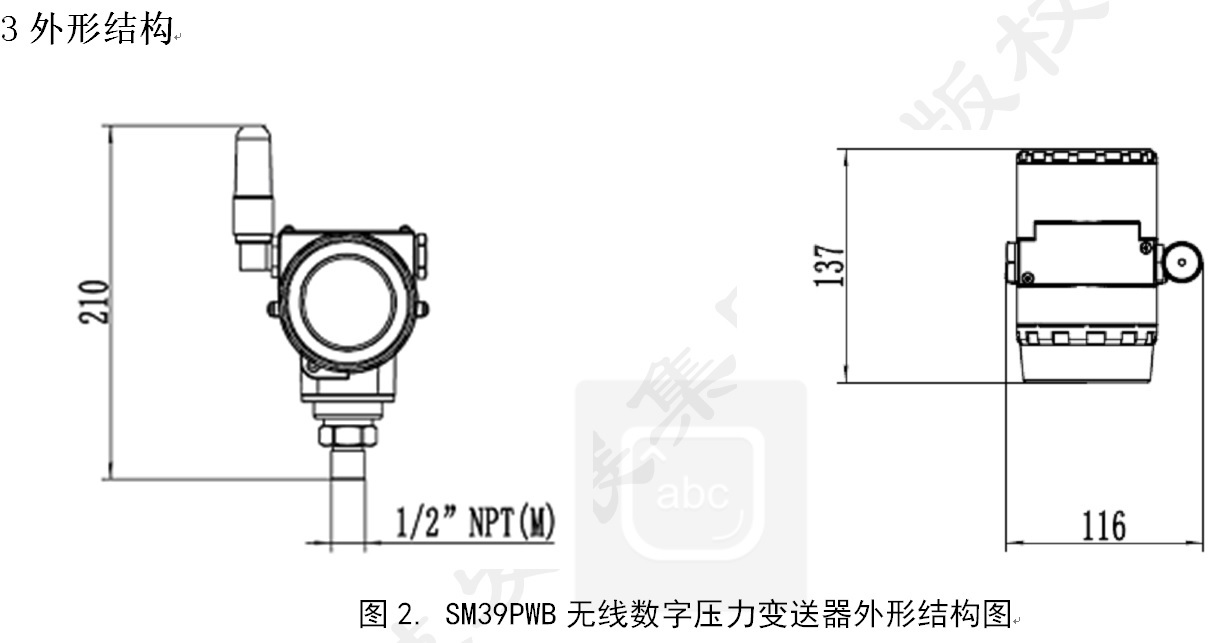

- Pressure transducer dimensions: Height 210 × Width 116 × Depth 137

- F8913 Module factory default well name: 123456 Network ID: 58418 Default physical channel: 13

- XBEE Module factory default network ID: 21 Default communication channel: 19 Default encryption enable: 0

Explosion-proof certification parameters

- Explosion-proof certificate number: CE18.2230X

- Explosion-proof mark: Ex ib ⅡC T4 Gb

- Rated voltage: 3.6V±1% Rated current: 50mA Rated power: 0.18W

3 External Structure

5. Instructions for Use

5.1. All transducers have undergone digital calibration, and different transducers have complete consistency and interchangeability;

5.2. During transportation, the batteries of all transducers are disconnected. When installing the pressure transducer on site, you need to unscrew the head cover and connect the battery. Be sure to tighten the sheath to prevent water leakage;

5.3. When installing the pressure transducer on the pipeline, first close the valve (needle valve or gate valve) on the pipeline where the pressure transducer is to be installed. There are two installation methods: (1). Screw the transducer directly into the upper port of the valve; (2) Screw the union or adapter into the upper port of the valve, and then screw the transducer into the upper port of the union or adapter. This installation method adds a union or adapter to adjust the direction. After installation, open the needle valve to confirm that there is no leakage, indicating that the installation is qualified;

5.4. If the temperature transducer is not used for a long time, please open the back cover and Disconnect the battery;

5.5. For detailed installation and debugging, please refer to the product operation manual.

6. Precautions

6.1. The battery model used in this product has passed explosion-proof inspection and certification, and the battery model is ER34615H; when replacing the battery, do not use other battery models.

6.2. The product antenna housing is made of plastic and has a potential electrostatic charge hazard! Avoid friction during use! Please wipe with a damp cloth when cleaning!

Keywords:

Related Applications

undefined

Language

Language