Solutions

Application Solution

Online detection control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

To ensure that the nominal weight and the actual weight of the product packaging match, the online automatic weighing system will conduct a full inspection of batch-produced items (before or after packaging), allowing substandard products to be reworked, effectively protecting the interests of consumers. At the same time, the automatic weighing machine ensures product quality and obtains a large amount of valuable signals. Manufacturers can grasp the product packaging accuracy and production capacity and other process statuses at any time, facilitating the prompt adoption of corresponding measures. It can not only timely control the underweight of items but also minimize the over-packaging of products.

1. System Composition

The entire system consists of entry components, metering components, sorting components, control components, and system printing components. The functions of each component are described below:

1.1 Entry Components

For smooth metering operations, the auxiliary conveying section at the front end of the metering section is called the entry section. The entry section performs the following three functions:

(1) Spacing Function: To maintain the minimum value between measured objects, the metering component can only place one measured object to correctly perform the measurement.

(2) Impact Prevention Function: To reduce the impact when the measured object enters the metering section, metering errors are generated due to the difference between the existing conveying speed and the metering section conveying speed, so the entry section is set at the front end of the metering section.

(3) Maintaining a Certain Speed Function: The conveying speed of the metering section and the entry section is maintained at a certain speed.

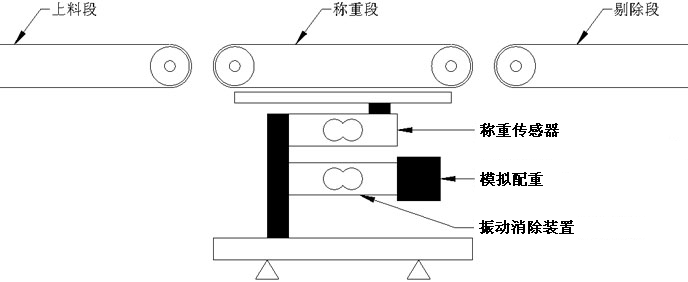

1.2 Metering Components

For the metering part of the items, a precision device installed on the load cell together with the metering conveyor and the running motor. When the measured object enters the metering section, the moment of entry is the starting point of the measurement. The entry of the measured object is measured and determined by the photoelectric sensor set at the entrance of the metering section, and the weight is determined after a system-set time.

1.3 Sorting Components

When the metering component sends a signal to the control component, a determination signal is generated according to the set value. The sorting section sorts the measured objects into lightweight, overweight, quantitative, metal detection, etc., in multiple stages.

1.4 Control Components

It includes the running motor of the entry section, the running motor of the metering section, the load cell and photoelectric sensor, the running motor and cylinder running signal of the sorting section, as well as functions such as weight display, set value, and quantity.

1.5 System Printing Components

According to the determination of the data, statistical data or set values are printed and output.

2. Product Functions

(1) Check the pre-managed product weight on the production line, sort the quantitative, underweight, and overweight products, and prevent substandard products from leaving the factory.

(2) Based on the standard weight of the product, sort the number of overweight or underweight products in the box or packaging box, and ship products that meet the standard quantity.

(3) Based on the standard weight of the product, sort the abnormal status of the product, and only ship excellent products.

(4) For assembled products, based on the standard weight of the product, measure and confirm whether spare parts and decorations are missing.

(5) This equipment is connected with other auxiliary devices to increase inspection efficiency and effectively manage production.

The food and fruit production line is connected with a metal detector to determine whether metal has flowed in and sort it.

Connect the scanner and inkjet printer to print the production date, batch number, and product weight on the product.

Install a printer to output the weight value, daily production, and production status by product.

For communication with the computer, product production management and warehousing management can be carried out.

3. Product Features

3.1 Weighing Body Section

(1) Stainless steel frame;

(2) All-aluminum alloy shell, conforming to NEMA4× (IP65) standard;

(3) NEMA4× (IP65) sealed connector;

(4) Shockproof self-adjusting feet, easy to install;

(5) Special belts produced using imported polyurethane materials;

(6) High-precision integrated load cell and electronic deviation sensor, realizing all-round protection of production;

(7) The weighing frame adopts a fully suspended installation structure, with higher accuracy and convenient system installation and maintenance;

(8) In special cases, an analog equalizer can be used to effectively eliminate the influence of external four-corner errors;

(9) Using roller-type ultra-quiet motor, stable and reliable, can run for a long time.

3.2 Control Section (Instrument)

(1) Using high-precision Σ-△ A/D conversion, 1,000,000 codes, high-speed sampling 200 times/second, meeting dynamic measurement;

(2) Chinese/English menu display, can be switched through parameters;

(3) Can accurately display real-time weight, qualified quantity, and unqualified quantity in real time, with a maximum display of 999999;

(4) Parameter password protection, data power-off protection function, data storage time can reach ten years;

(5) Weight deviation alarm output function, can be externally connected to sound, light alarm or other equipment;

(6) Automatic interlocking shutdown function, convenient for users' front and rear hardware interlocking control;

(7) Deviation query function during standby;

(8) Using RS485 communication interface, optional support for DEVICENET, MODBUS, PROFIBUS and other communication protocols. Used to upload the instrument's working status, qualified quantity, and unqualified quantity in real time;

(9) With adjustable speed output function (external control VFD);

(10) The control instrument adopts panel mounting, all-metal structure, waterproof PE panel, IP65 sealing protection level;

(11) Optional: upper and lower weighing conveyors, push-rod type rejector (mechanical type).

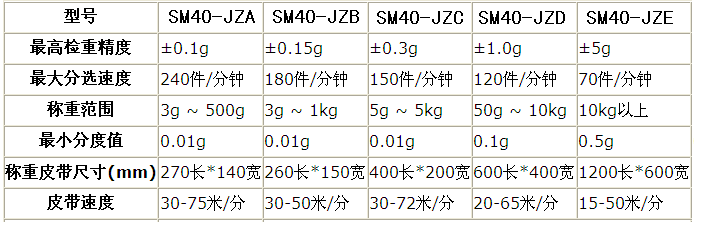

4. Technical Specifications

5. Process Flow Chart

6. Application Notes

(1) Inspect the number of products

Inspect the number of items in the package to see if it meets the specified number, to avoid underfilling (missing) or overfilling.

(2) Product Classification

The weight of the measured object is uncertain, but it needs to be classified by weight, such as agricultural, sideline, fishery, and animal husbandry products classified by weight grade, and it can also be used in the machinery manufacturing industry for the classification of parts.

Previous:

Next:

Language

Language