Solutions

Application Solution

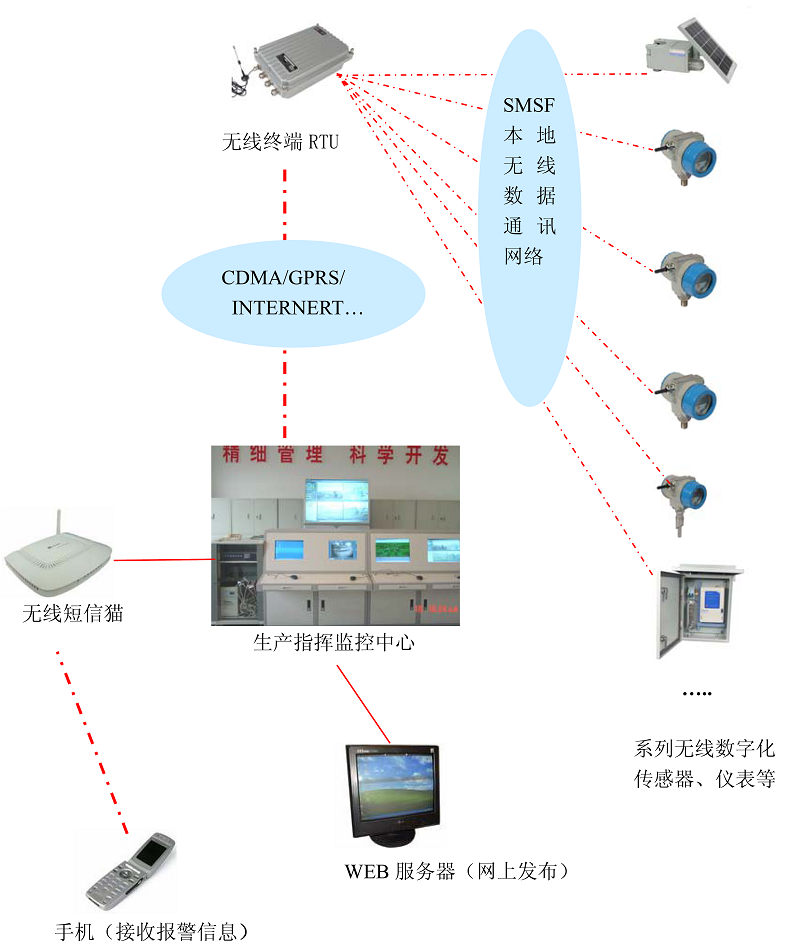

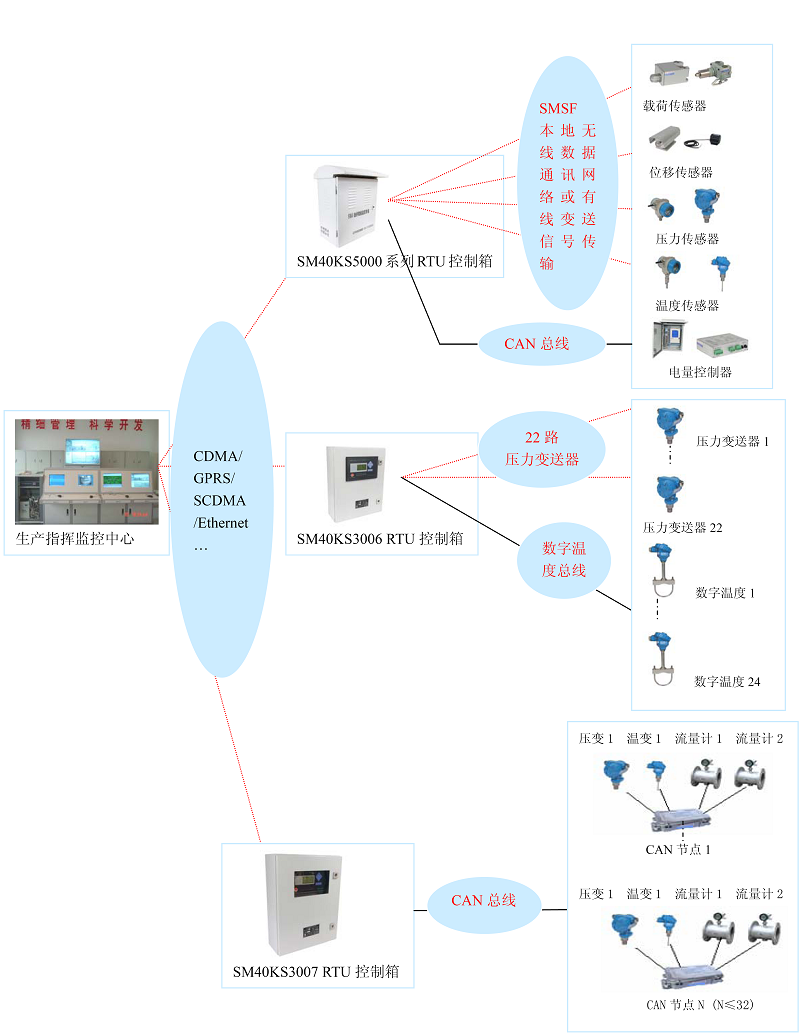

Industrial data acquisition and remote monitoring and control system based on IoT application

Category:

Weighing solutions

Publish Time:

2020-07-10

Internet of Things Applications

Application Scope

Widely used in the industrial automation monitoring and control fields such as petroleum, chemical industry, and building materials. Through digital monitoring and control, information-based command, intelligent scheduling, and networked management, it realizes unattended operation and remote monitoring and control of monitoring and control equipment.

System Advantages

1. Modular design, high redundancy: Terminal digital sensor data acquisition → intelligent monitoring and control terminal RTU → upper computer APPSERVER management → online publishing, forming a hierarchical IoT network, facilitating decentralized monitoring and control, and centralized management.

2. Multiple industrial fieldbus communications: RS485, CAN-BUS, 1-Wire bus selectable;

3. Local wireless data communication: SMSF local wireless data communication network networking, realizing industrial production data acquisition and control; simplifying on-site installation, reducing abnormal damage failures of signal cables, and improving the overall system's long-term operation resistance to damage and reliability;

4. Remote wireless data communication: RTU has multiple communication interfaces and is compatible with various communication systems such as GPRS/CDMA/SCDMA/Internet.

System Composition

1. Digital sensors: Standardized digital signal wired or wireless sensors, such as load, displacement, angle, speed, acceleration, temperature, weight, pressure, electric energy, and various other sensors or transducers.

2. Standardized interface RTU: Docking with SCADA, DCS, and other network systems, sharing data sources, and realizing IoT applications with industrial production scheduling and management systems.

3. APPSERVER software: Collects data from various RTUs; sets upper and lower limits of parameters and over-limit alarms; sets digital temperature channels and analog channels; remotely sets RTU parameters and upgrades RTU programs, simple operation and maintenance;

Technical Indicators

1. RS485 extended communication: EIA-RS485-A standard, photoelectric isolation, isolation voltage 1000Vdc/1 minute; supports Modbus RTU or other third-party customized communication protocols; can be connected to other third-party equipment on site.

2. Ethernet communication: 10BASE-T PHY, compatible with 100/1000 BASE-T network.

3. RS232 communication: 3-wire or 9-wire, compatible with various communication systems such as GPRS/CDMA/SCDMA DTU.

4. CAN-bus communication: CAN Specification Version 2.0 standard.

5. SMSF local wireless data communication network, effective communication distance ≥300m; carrier frequency: 433MHz, belongs to the ISM working frequency band, no frequency point application required; GFSK narrowband modulation, and forward error correction channel coding and decoding technology is adopted to improve the reliability of data communication under low power consumption; it can be used as a wireless digital sensor interface, or as a data communication link interface between RTUs. It can be customized to ZigBee or other standard local wireless data communication network interfaces according to needs.

Previous:

Language

Language