Solutions

Application Solution

Compound (BB) fertilizer formulation control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

【Introduction】

BB fertilizer, short for Bulk blending fertilizer, is a type of compound fertilizer made by blending several granular single fertilizers or compound fertilizers in a certain proportion. It is characterized by the ease of adjusting the proportions of nitrogen, phosphorus, potassium, and trace elements, allowing for the production of various specifications of specialized fertilizers to meet user needs, particularly suitable for soil testing and formula fertilization. Due to its flexible and variable nature, under the control of a microcomputer, the required fertilizer can be produced within minutes.

1. Advantages of BB Fertilizer

(1) Comprehensive nutrients, high concentration, significant increase in yield and cost reduction, and strong targeting. Its total nutrient content is generally above 52%, while the effective components of domestically produced compound fertilizers currently on the market are around 25%, and the total nutrient content of imported compound fertilizers is mostly 45%-48%. However, the phosphorus proportion in imported compound fertilizers (N:P2O5:K2O=15:15:15) is relatively high, resulting in significant nutrient waste. The nutrient ratio of BB specialized fertilizers is proposed based on the characteristics of crop nutrient requirements and local soil nutrient supply, making it both scientific and targeted.

(2) Simple processing, low production cost, and no pollution.

(3) Flexible formulation. It can be flexibly adjusted according to different crop nutrition, soil fertility, and yield levels, compensating for the shortcomings of general-purpose compound fertilizers, which tend to cause deficiencies or excesses of certain nutrients due to fixed nutrient ratios. BB fertilizer can be used for both basal and topdressing. Due to its good solubility, it is suitable for surface application as basal fertilizer and should not be applied too deep. For fruits, tea, and vegetables, BB fertilizer should not be broadcast, but should be applied in strips or holes, 3-5 cm away from seeds and crop roots, covered with soil after application, and topdressed with water. The amount of application per mu is only 60% of that of imported compound fertilizers.

2. System Composition

Riyue Science and Technology Development Group is a domestic manufacturer specializing in the research and development and production of fertilizer control equipment. The SM40 compound (BB) fertilizer batching control system mainly consists of a computer control system, quantitative batching speed-controlled belt scales, belt conveyors, spiral conveying mixers, elevators, automatic quantitative packaging machines, belt conveying sealing machines, air pumps, motors, and control systems; among them, the SMC-2000 quantitative batching belt scale, SM40-2005 belt scale dedicated batching controller, SM40-3000A packaging scale controller, and its packaging scale control system are the main products of Riyue Science and Technology. They have received high praise from users in the fertilizer industry.

3. System Operation Process

(1) Raw material preparation and pouring into the hopper. Turn on the system power and air pump;

(2) Set the material formula (ratio) and total output (hourly output) on the computer according to the target formula;

(3) Start the elevator, spiral conveying mixer, and belt conveyor in sequence;

(4) Start batching on the computer;

(5) Continuous discharge and automatic packaging;

(6) Sealing and finished product output.

4. Functions and Features

(1) Multiple batching types. Applicable to 3-12 materials;

(2) High degree of automation. The entire batching, mixing, and packaging production process is controlled by a computer system;

(3) Large production capacity. High batching accuracy and speed, capable of batching 8-40 tons per hour;

(4) Accurate measurement. It can print reports and query instantaneous batching accuracy at any time to ensure the accuracy of batching, mixing, and packaging;

(5) Uniform mixing. Cage-type stirring ensures uniform mixing, reliable operation, and prevents stratification during the production process;

(6) Reasonable design. Individually designed for your site, with reasonable land occupation and compact structure;

(7) Easy formula adjustment. Computer-controlled, fertilizer formula can be changed and adjusted at any time;

(8) Electrical interlock control function to ensure no blockage or spillage.

5. Technical Indicators

(1) System control accuracy: ±0.5%

(2) System measurement accuracy: ±0.5%

(3) Ratio adjustment accuracy: ±0.1%

(4) Hourly output range: 0.1-1000 tons/hour

(5) Ambient temperature: -10℃~+45℃

(6) Relative humidity: 0-90%RH (no condensation)

(7) Power supply voltage: 380V±10%,220V±10%;50Hz

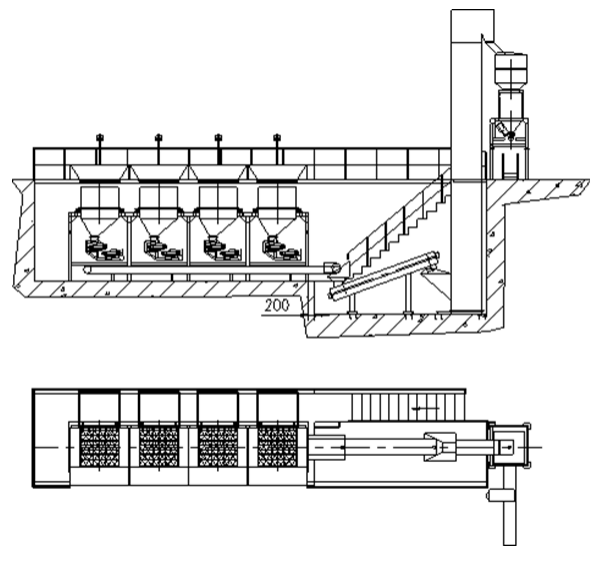

6. System Layout Diagram

Layout Diagram

On-site Picture

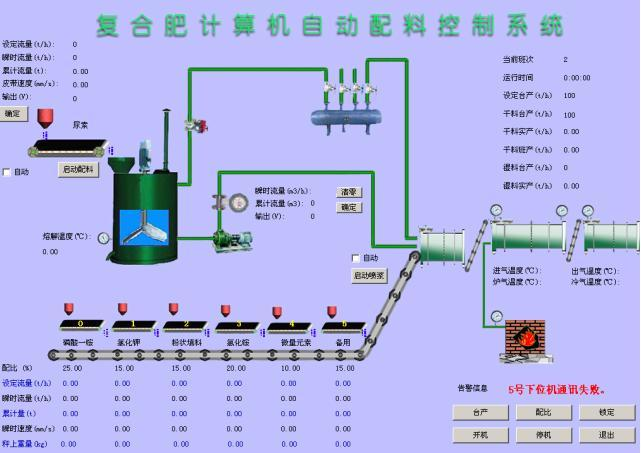

7. Software Function Introduction

7.1 Compound Fertilizer Computer Automatic Batching Control System

System Functions:

(1) Urea output setting function, with real-time reading of urea instantaneous flow rate, cumulative amount, and belt speed;

(2) Real-time measurement of urea melting tank temperature, and the size of the incoming air can be adjusted in real-time according to the temperature inside the tank using PID control;

(3) Spraying flow rate adjustment function, which can measure the instantaneous flow rate and cumulative amount in real time;

(4) Spraying start and stop control function;

(5) Real-time detection of inlet temperature, furnace gas temperature, outlet temperature, and cold air temperature;

(6) Dry material formula setting, output adjustment, and output statistics function;

(7) Report statistics, data query, and printing function;

7.2 Fully Automatic Microcomputer Batching BB Fertilizer Production Line

System Functions:

(1)Capable of real-time reading of raw material instantaneous flow rate, cumulative amount, and belt speed values;

(2)Belt scale deviation, slippage, and flow rate upper and lower limit alarm functions;

(3)Alarm query and printing functions;

(4)Control system start and stop control functions;

(5)Recipe setting, output adjustment, and output statistics functions;

(6)Report statistics, data query, and printing functions;

Previous:

Language

Language