Solutions

Application Solution

Dry-mixed mortar industry applications and solutions

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

In recent years, with the guidance of relevant national policies, China's dry-mixed mortar industry has developed rapidly. The industry management departments and related enterprises in various provinces and cities have closely cooperated to continuously explore industry development models with different characteristics. The mortar industry involves three main links: production, storage and transportation, and use. Production and use links are not discussed here. The storage and transportation link, as the intermediate process connecting production and use, links mortar production units and their direct users. Its management directly affects the operating costs of production enterprises and user satisfaction. Mortar storage and transportation is a very complex process, including not only the management of transport vehicles but also the operation of mortar storage silos. Traditional mortar storage and transportation management mainly has the following problems:

Because mortar production units cannot obtain timely information on the current remaining amount of on-site storage silos, they cannot proactively organize effective transportation, leading to frequent shortages and surpluses on site, causing serious waste of transportation resources and affecting the enthusiasm of construction sites in using mortar. Because dispatchers cannot know the location of transport vehicles, they cannot provide prompts for situations where drivers are unfamiliar with the roads and take detours during delivery. They are also unable to detect phenomena such as drivers speeding, illegal unloading, and unauthorized use of company vehicles. These not only increase transportation costs but also bring great safety hazards. The weighing sensors of the storage silos are easily damaged by the harsh environment on the construction site. Once the sensors are damaged, the weighing system will be unable to measure normally and needs to be maintained immediately. If the on-site feedback is not timely or the maintenance personnel are not arranged in time, it will seriously affect user satisfaction. In some areas with many mortar production enterprises, there is often a situation where a construction site is supplied by multiple mortar plants, which often leads to the construction site secretly using mortar from other mortar plants. Because the on-site usage cannot be known, it is later discovered that the actual usage is far less than the agreed usage. Mortar enterprises cannot know the daily usage of the construction site and cannot make realistic production and sales plans in advance, and management levels cannot be improved. On the other hand, as an industry management department, the association needs to know various industry data such as the production and use of dry-mixed mortar in the process of industry management and policy formulation, using data as a basis for decision-making. However, the data obtained by the association can only be reported by enterprises through monthly and annual reports. Not only is the authenticity of the data unverifiable, but the data is often delayed for a considerable period of time. How to solve the above problems will be introduced in Chapter 1, Functional Features.

Keywords: Dry-mixed mortar, Production, Storage and transportation, Use

1. Functional Features

In order to solve the above problems and truly improve the management level of dry-mixed mortar storage and transportation, our company, after careful research, finally uses information technology to integrate the real-time location information of dry-mixed mortar storage silos, mortar remaining amount information, and the location information of transport vehicles onto a unified network office platform for industry management and enterprise operation, and has achieved:

(1) When the remaining amount of mortar in the storage silo is insufficient, the dry-mixed mortar system platform will automatically issue a shortage alarm. The dry-mixed mortar production enterprise can proactively contact the construction unit to inquire about the order and arrange production and transportation in advance, completely solving the problems of "material shortage" and "material surplus" and improving the timeliness of dry-mixed mortar logistics services.

(2) Through the dry-mixed mortar system platform, the transportation process of the transport vehicle can be monitored throughout the entire process, and information such as the current location and speed of the vehicle can be obtained at any time to judge the vehicle's unloading status and improve vehicle use efficiency. Functions such as historical playback and speeding alarms can also be used to reduce or eliminate detours, reducing management costs.

(3) When an abnormality occurs in the weighing sensor of the storage silo, the dry-mixed mortar system platform automatically alarms, and the management personnel can find the faulty sensor in the office and use appropriate methods to ensure that the storage silo can still be used normally in the short term even if one sensor is missing. Maintenance personnel can reasonably arrange maintenance plans according to work needs, improve maintenance efficiency, reduce maintenance costs, change the previous passive waiting for construction site repair service methods, and enhance customer service satisfaction.

(4) When the weight of the storage silo increases, and it is not a vehicle from this mortar plant that is adding material, the dry-mixed mortar system platform can issue an illegal filling alarm to remind the mortar plant to pay attention, which can effectively prevent the construction site from secretly using mortar from other mortar plants.

(5) The dry-mixed mortar system platform automatically generates mortar filling reports and daily usage reports as a reference for external settlement and internal production and sales planning. At the same time, the system platform provides remote weight calibration and weight zeroing functions for mortar plant users, so that the storage silo calibration work can be carried out directly at the computer, reducing a large amount of maintenance work.

2. Industry Overview

2.1 Production Stage

2.1.1 System Overview

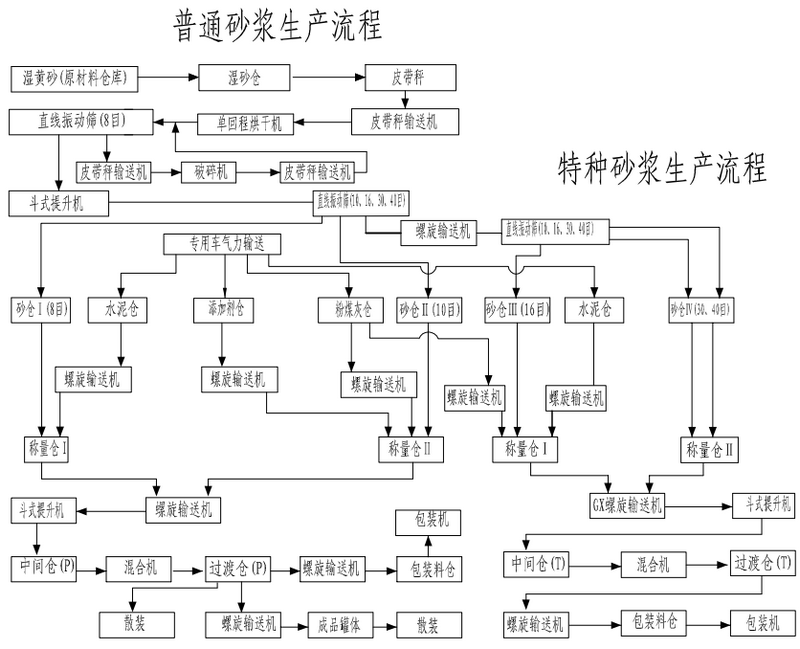

Our company is one of the first domestic manufacturers to design, develop, and produce a complete set of dry-mixed mortar control equipment. The dry-mixed mortar production line control system developed and produced by our company adopts a DCS control mode and is designed as a plant-wide computer monitoring system for the entire plant's total production process. It realizes the integration of production process monitoring and management, making the entire plant not only have advanced process control automation in production but also modern management (ERP). It is also of great significance to improving output, stabilizing quality, and reducing energy consumption. This production line control system draws on successful control systems currently used in ready-mixed concrete mixing plants and belongs to distributed control system (DCS). It includes multiple subsystems and has advantages such as strong versatility, flexible combination, and high reliability. The system adopts standardized, modular, and serialized design and has a hierarchical system structure with decentralized control and centralized integrated management. The system has high automation, strong anti-interference ability, fast and accurate batching speed, stable performance, simple operation, and flexible configuration. It is an intelligent batching control system specially designed for dry-mixed mortar plants. It uses reliable Advantech industrial control computers, Siemens S7300 PLC, our company's self-developed SM40-HXC batching control instrument, SM40-CG-CAN management machine (SM40-I/O-F type industrial control box), and electrical components from well-known domestic and foreign manufacturers. The software adopts user-friendly design, with illustrations and text, a full dynamic simulation production interface, full Chinese display, and a clear view of the on-site conditions. It automatically controls, monitors, and manages the entire production process from material conveying, metering, unloading, mixing, and discharging.

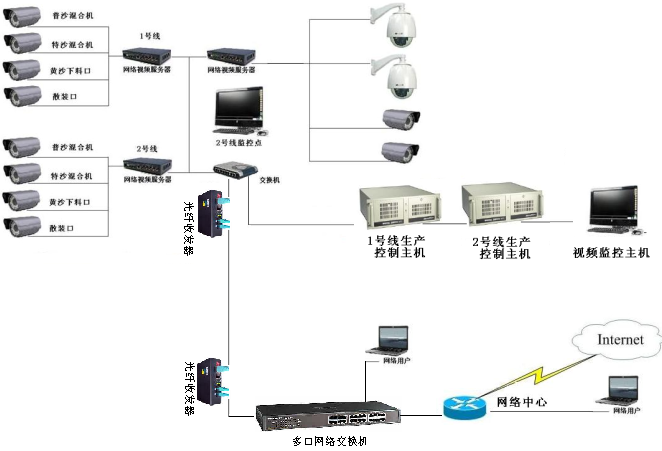

2.1.2 Network Interface Topology Diagram

2.1.3 System Process Flow

2.1.4 System Features

(1) Centralized control and on-site control are combined. Centralized control mainly uses industrial control computer control and manual control on the operation panel. On-site control uses manual operation according to the configuration of on-site equipment. The two are independent and have interlocks.

(2) The operation panel is designed with user-friendliness, making it easy for operators to avoid fatigue and improve production efficiency. It is also equipped with a simulation process screen, which is elegant, clear, easy to operate, and durable.

(3) Using Advantech industrial control computers and Siemens PLC can ensure stable operation of equipment in complex production environments and reduce system failures.

The entire control process is controlled by an authorized open setting, which is flexible and convenient to meet customer needs.

The system displays in full Chinese, with parameter settings, numerical input, and dynamic simulation of the production process, making it easy to operate.

Complete report statistics, powerful real-time and historical data query, timely and accurate reflection of production status, allowing management personnel to understand the production status at any time and conduct decision analysis.

The system has automatic historical tracking records, recording the relevant modified operation content, which is convenient for administrators to track and maintain.

Manual batching, computer automatically records the consumption of various materials manually. Perfect consumption statistics of manually batched materials.

Raw material transfer warehouse selection can be realized. When a certain warehouse is out of material, other warehouses with the same material can be selected to ensure normal production operation.

The computer prompts and displays various equipment operation fault information in real time.

According to production needs, automatic compensation or non-compensation functions and automatic correction of drop difference can be selected to meet actual production needs.

The system can also control the entire production process through a simulation screen.

The system also manages the storage of materials in the warehouse, displays the status of raw materials in each warehouse, and promptly alarms.

Real-time video monitoring function for the entire factory.

2.1.5 Integration with ERP system

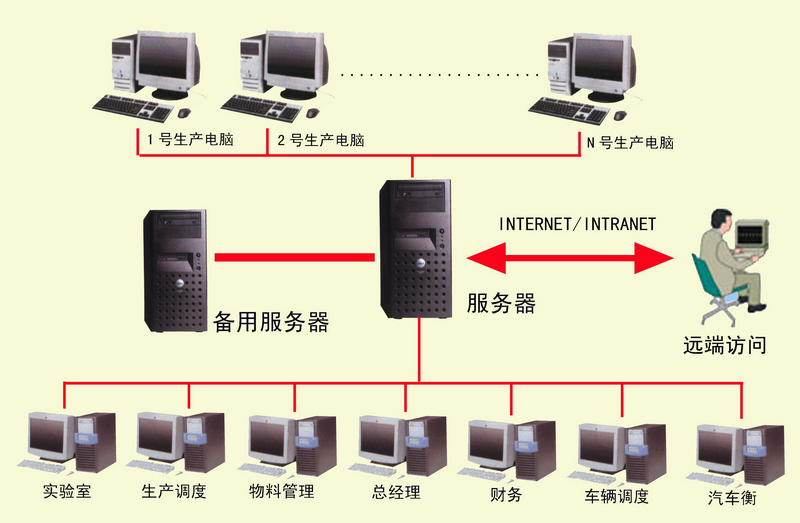

The control system host software uses SQL database design and has networking capabilities. Through data interaction with the weighing room computer, production computer, and material dispensing computer, it is simultaneously sent to the server for summary processing, and the server host software can be called the enterprise ERP production and sales management system. The enterprise production scheduling room, sales department, and other relevant functional departments can access the data on the server through the network. The system has the following characteristics.

(1) Effectively grasp accurate information: The system assigns different permissions to different departments and personnel of the customer, so that sensitive data (such as sales contracts, delivery data, etc.) can be timely supervised and confirmed by the backend personnel, greatly improving the accuracy of enterprise business data.

(2) Standardized enterprise processes: The system integrates the procurement, production, sales, delivery, and payment processes of the customer. All employees must work under these fixed rules, helping enterprises standardize management standards.

(3) Improve capital operation: The established ERP enterprise management system makes communication between departments convenient and fast, improving operation speed and efficiency. At the same time, every purchase and sale can be timely reflected as a change in the capital flow, and managers can monitor the capital flow and flow rate of the enterprise at any time.

2.2 Storage and transportation, usage aspects

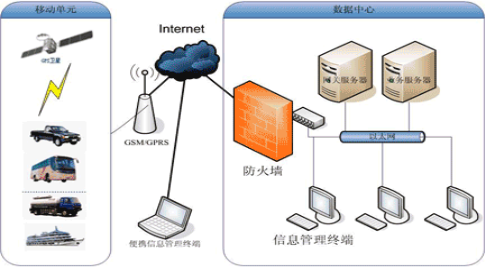

2.2.1 System topology diagram

2.2.2 Construction site metering topology diagram

2.2.3 Construction site metering control equipment

It mainly consists of four parts: digital sensor group, digital junction box, dry powder mortar intelligent controller, and intelligent electric control box, realizing weighing data acquisition, digital processing, and automated control. Integrating GPS/GPRS wireless communication module to complete positioning data reception, comprehensive weighing, and sending positioning data to the background communication service system.

2.2.4 Vehicle-mounted GPS equipment for transportation

Mortar transport vehicle-mounted positioning communication equipment. Using GPS global satellite positioning technology, it uploads vehicle location and vehicle status information to the background communication service system in real time. It achieves the purpose of monitoring vehicle speed and driving routes.

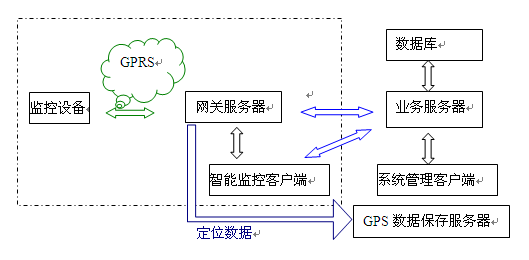

2.2.5 Background communication management service system

The communication channel connecting various terminal devices and the front-end monitoring center has the following tasks:

(1) Data processing center. This part is the control core of the entire system, including related servers, network connection devices, wireless communication systems, and related software systems. This part is placed in the background service center. Companies can access through the Internet.

(2) Use a fixed IP address to receive GPRS data packets and send them to various monitoring clients on the Internet.

(3) Store the received data and have certain functions such as data classification display, backup, and restoration.

(4) It has data sending selection function, and sends relevant equipment information to designated users according to user identity to ensure data transmission security.

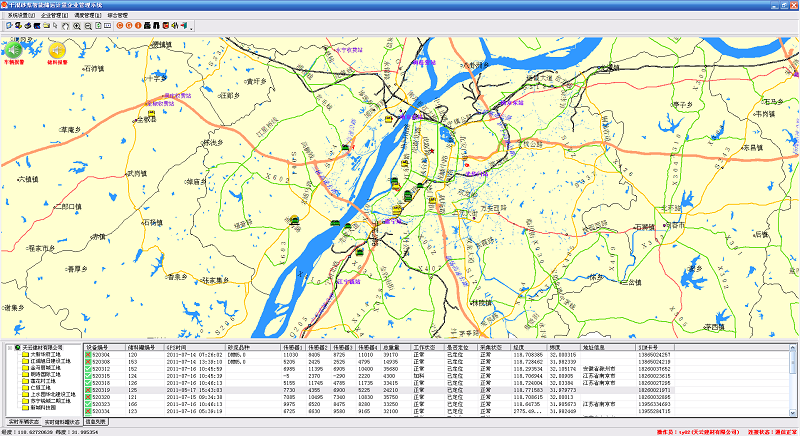

2.2.6 Front-end monitoring center

(1) The front-end monitoring center system is designed and developed around the dry-mixed mortar monitoring requirements, and is an integrated monitoring information center software integrating tank weighing, positioning, and vehicle positioning monitoring. All positioning information returned by the GPS terminal and tank weighing status information are displayed on the map of the front-end software. The front-end software can also conveniently check the historical information of the vehicle and replay it, and complete interactive tasks such as issuing control commands.

(2) The monitoring center computer equipment connects to the background communication management service system through the Internet, and selects whether to equip handheld devices and large-screen projection equipment according to actual needs.

3. Conclusion

Although dry-mixed mortar has encountered various obstacles in its promotion and use, its historical inevitability of replacing traditional mortar is difficult to change. Not only in Shanghai, Jiangsu, and Zhejiang, but also in other large and medium-sized cities, there is great interest in using dry-mixed mortar. Extensive media publicity and the continuous technological progress made by numerous scientific and technological workers will create favorable conditions for the development of dry-mixed mortar. Just like the development of commodity concrete, it will surely usher in a bright spring.

Language

Language