Solutions

Application Solution

High-precision data acquisition system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

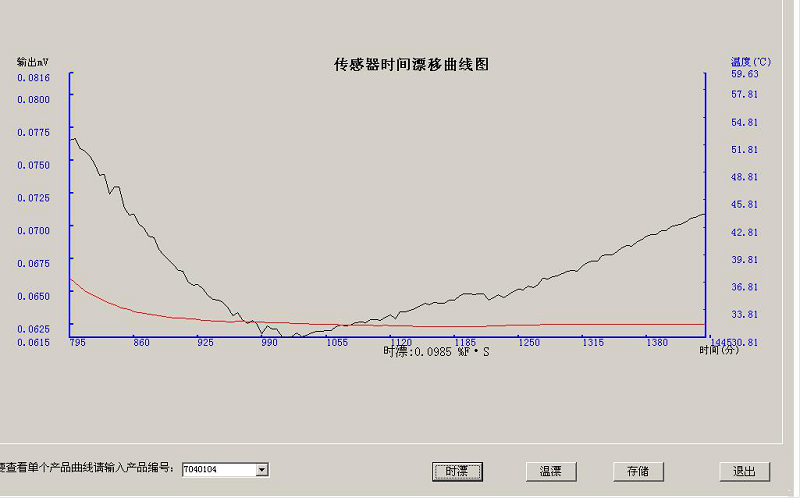

In some special measurement and control fields, we need to acquire sensor signals from many channels at high speed and high precision simultaneously. Previously, we could only use industrial multi-channel data acquisition boards for AD signal acquisition, but they have many problems such as few acquisition channels, low acquisition accuracy, and slow sampling speed, which seriously restricts the development of industrial automation. Based on this, after years of research, Riyue has developed a new generation of high-precision multi-channel data acquisition system. A single machine can acquire up to 32 channels, and after networking, a subnet can acquire 96 analog signals, with a sampling resolution of 24 bits and a sampling speed of 100 Hz. It has been widely used in temperature and time drift aging, compensation testing, and laboratory force machine measurement by sensor manufacturers.

Keywords: High precision, Data acquisition, Resolution, Temperature drift, Compensation, Laboratory force machine

1. System Composition

The SM40 high-precision multi-channel data acquisition system mainly consists of a multi-channel data acquisition system and host computer control software. The multi-channel data acquisition device includes 8 24-bit high-precision acquisition boards and 2 temperature acquisition parts, with an on-board RS485 serial communication interface. It can fully meet the needs of real-time high-precision acquisition in various industries. The control software is written in C++ high-level language, with rich software setting interfaces and a user-friendly setting interface, and has the functions of real-time data acquisition for multiple channels (single channel) and real-time data playback. In addition, the playback data can be displayed as curves for easy data analysis.

2. System Overview

The SM40 high-precision multi-channel data acquisition system is a device used for multi-channel signal acquisition. Its analog sampling uses advanced foreign Σ-Δ analog-to-digital conversion technology and high-speed digital processing technology. By digitally processing the weak weight signals output by symmetrical load cells (transducers), high-precision signal data is obtained. The system has strong anti-interference performance, high stability, and good reliability. The system uses a single-chip microprocessor as the CPU and has built-in rich numerical filtering software. It has a power-down data saving function.

This machine has a good human-machine interface and rich digital processing software, and is equipped with multiple status indicator lights. The standard RS485 communication interface can be used with IPC, DCS, etc., to form a monitoring system.

3. System Functional Characteristics

(1) Can be used for all resistance strain-type force, weighing sensors or transducers;

(2) High-brightness multicolor LEDs are used as status indicators;

(3) Anti-electromagnetic interference, low electromagnetic leakage radiation, impact resistance, corrosion resistance;

(4) IP65 protection level front panel is waterproof, dustproof, and easy to clean;

(5) Uses high-precision Σ-Δ analog-to-digital conversion;

(6) Has a self-diagnosis function when the power is turned on;

(7) The system has a built-in multi-channel temperature acquisition function;

(8) A single machine can acquire 32 channels, and the system can be freely expanded and combined, with a maximum of 96 acquisition channels;

4. Technical Indicators

(1) Power supply: 180VAC~250VAC, 50Hz. Maximum single-unit power 100W;

(2) AD signal range: mV: -10mV~+30mV, mA: 0~20mA, V: 0~10V;

(3) LED operating indicator: 5 three-color LEDs (RXD, TXD, ERR);

(4) Sampling speed: 50~100 times per second

(5) Nonlinear error: Better than 0.003%F·S

(6) Drive capability: Maximum 2KΩ (single channel);

(7) Communication interface: 1. Standard RS485 format (free port protocol);

(8) Environmental requirements: Temperature range -40~80℃, humidity <90%RH (no condensation);

6. System Test Interface

Language

Language