Service and Technology

Service and Technology

How to install a tilt sensor?

Category:

Relevant sensor technology papers

Publish Time:

2021-08-20

Tilt sensors are commonly used in systems for level measurement and can also be used to measure changes in tilt relative to a horizontal plane. In some tilt sensor applications, the angular error requirement is not high, but in other cases, it is very strict. In terms of angular error, in addition to the inherent properties of the sensor itself, there are also certain requirements for sensor installation. Incorrect installation can lead to errors in measurement.

Installation Precautions:

1. Tilt sensor installation methods are divided into horizontal and vertical installation. However, whether horizontal or vertical installation, during installation, the sensor mounting surface should be kept parallel to the surface of the object being measured, while reducing the influence of dynamics and acceleration.

2. The mounting surface should be rigid, hard, and smooth, and the sensor should maintain rigid contact with the mounting surface.

3. During installation, even force should be applied to avoid excessive mechanical force causing deformation of the mounting surface and resulting in installation errors. The sensor needs to be firmly fixed to avoid shaking causing data jitter.

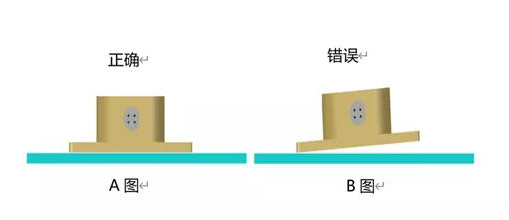

4. In addition to keeping the sensor mounting surface parallel to the surface of the object being measured, the sensor cable must also be kept parallel to the axis of the measured surface, i.e., the two axes cannot have an angle. To avoid unnecessary errors, the mounting surface and the measured surface should be in complete contact. During the installation of the tilt sensor, strict attention should be paid to the "two surfaces" and "two lines," which helps to improve data accuracy.

1) "Two surfaces" refers to the sensor mounting surface and the mounting surface of the object being measured being completely close together (the mounting surface of the object being measured should be as horizontal as possible), and no angle can be produced (such as the angle in Figure B). If it is not flat, it may cause installation errors and tilt measurement errors. The correct installation method is shown in Figure A.

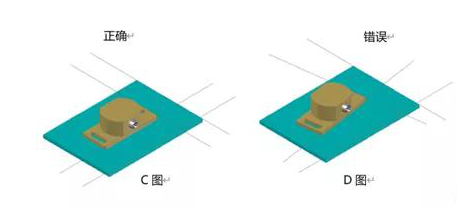

2) "Two lines" means that during installation, the sensor measurement axis should be as parallel as possible to the measured direction, and the influence of dynamics and acceleration on the sensor should be reduced, and the two axes cannot have an angle (such as the angle in Figure D). If the installation is not parallel, cross-axis errors will occur, causing the tilt measurement error to increase. The correct installation method is shown in Figure C.

2) "Two lines" means that during installation, the sensor measurement axis should be as parallel as possible to the measured direction, and the influence of dynamics and acceleration on the sensor should be reduced, and the two axes cannot have an angle (such as the angle in Figure D). If the installation is not parallel, cross-axis errors will occur, causing the tilt measurement error to increase. The correct installation method is shown in Figure C.

5. Do not connect a power supply with a voltage higher or lower than the standard voltage value to the sensor, and do not disassemble the sensor privately, so as to avoid damage to the stability and protection of the product.

6. After the tilt sensor is installed, check the current angle value. If the current angle value is not zero, the relative zero point needs to be set, that is, the current installation position is set as the zero point. Most tilt sensors have a built-in zero adjustment system. Customers can customize the zero adjustment button according to their requirements to achieve certain angle zeroing performance, that is, before use after installation, the zero button can be used to achieve zeroing performance, which facilitates angle reading and reduces unnecessary errors.

Language

Language