Products

PRODUCT CENTER

SM39-DH01P HART protocol intelligent pressure transmitter

Category:

1. Overview

SM39 The DH01P HART protocol intelligent pressure transmitter is a high-precision, high-stability, multi-parameter, 4.5-digit LCD display intelligent pressure measurement product that complies with the HART protocol. Users can use the HART communicator to manage, adjust, or monitor process variables of the HART instrument in operation, or use buttons for on-site configuration, which is convenient to operate. With precise digital temperature compensation and non-linear correction technology, safe and reliable explosion-proof structure design and standardized signal output, it features high accuracy and a wide range of measurement, suitable for occasions requiring precise measurement of fluid pressure. This product works in a two-wire mode and can directly replace analog two-wire 4~20mADC output transmitters. It can be widely used in various fields such as petroleum, chemical industry, steel, power, building materials, textiles, pharmaceuticals, food, gas, scientific experiments, and military industry. It has been widely used in various oil fields such as Daqing, North China, and Xinjiang, and has won user recognition for its high precision, high reliability, simple installation, convenient maintenance, environmental protection, and durability.

2. Features

·4 ~20mA current output superimposed with HART protocol digital communication (two-wire);

· Digital compensation and non-linear correction technology is used;-10 ℃ ~80 ℃ Digital wide temperature compensation;

· Local and remote zero point and span adjustment functions;

· On-site button operation for convenient configuration;

· Protection level IP65.

3. Performance Indicators

Table 1. Performance Indicators of SM39-DH01P HART Protocol Intelligent Pressure Transmitter

|

Unit |

KPa |

MPa |

|||||||||||

|

Measurement Range |

0-70 |

0-100 |

0-200 |

0-350 |

0-700 |

0-1.0 |

0-2.0 |

0-3.5 |

0-7.0 |

0-10 |

0-20 |

0-35 |

0-70 |

|

Upper Limit |

70 |

100 |

200 |

350 |

700 |

1.0 |

2.0 |

3.5 |

7.0 |

10 |

20 |

35 |

70 |

|

Over Range |

100 |

150 |

300 |

500 |

1000 |

1.5 |

3.0 |

5.0 |

10 |

15 |

30 |

52 |

100 |

Accuracy: ±0.1%FS (typical), ±0.25%FS (maximum)

Zero temperature error: ≤±0.25 %FS (within the entire working temperature range)

Span temperature error: ≤±0.25 %FS (within the entire working temperature range)

Long-term stability: ≤±0.25 %FS/year

Compensation temperature: -10℃~80℃

Operating temperature: -20℃~80℃

Storage temperature: -40℃~85℃

______________________________________________________________________________________

Power supply: (15~30) VDC

Digital output: (4~20)mADC output superimposed with HART protocol digital communication

Display: LCD display, two/three-button control

Damping: (0~32)s

Load capacity: (U-12V)/0.02Ω

Insulation: 100MΩ/50V

Explosion-proof certificate number: Explosion-proof certificate number: CE18.1519 Explosion-proof mark: EXd IIC T6 Gb

______________________________________________________________________________________

Vibration: 20g, (20~5000) Hz

Shock: 20g, 11ms

Diaphragm: 316L stainless steel/tantalum

Pressure connection: 1Cr18Ni9Ti stainless steel/Hastelloy C

O Shaped sealing ring: Fluororubber

Weight: Approximately 1.7kg

______________________________________________________________________________________

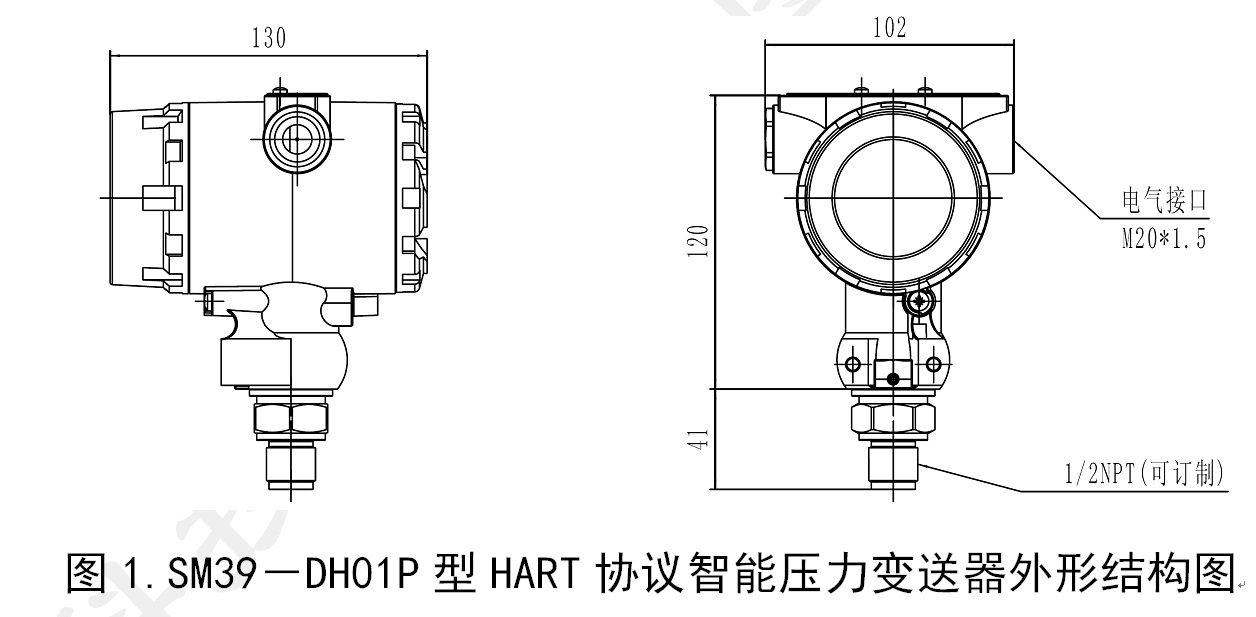

4. External Structure

See Figure 1. External Structure Diagram of SM39-DH01P HART Protocol Intelligent Pressure Transmitter (Unit: mm)

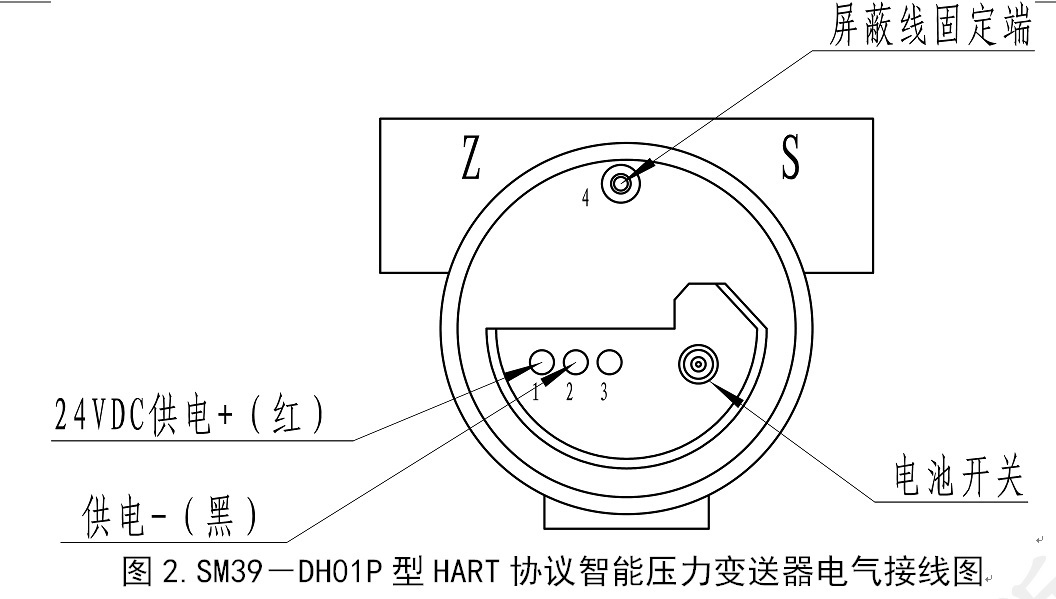

5. Electrical Wiring

Open the instrument back cover (wiring terminal panel) to see the wiring terminals. For power connection, see Figure 2: The left end 1+ (red) and 2- (black) are for sensor power supply and signal wiring, and terminal 3 is reserved. On the right side, there is a rotary switch for controlling battery power supply, and terminal 4 at the top is used to fix the signal line shielding wire.

6. Instructions for Use

6.1. All sensors have undergone digital calibration, and different sensors have complete consistency and interchangeability.

6.2. During transportation, the batteries of all sensors are in the off state. When installing the pressure sensor on site, open the back cover, turn the rotary switch to the "ON" position, and the LCD will display normally, indicating that the battery has been successfully connected. Connect the sensor power supply and signal wires to the left end 1+ (red) and 2- (black) of the 3-pin terminal, install and tighten the back cover. Be sure to tighten the protective sleeve to prevent water leakage.

6.3. To install a pressure sensor on a pipe, first close the needle valve at the sensor installation location; then wrap the sensor threaded connector with Teflon tape; screw the sensor into the pipe connector; open the needle valve and check for leaks. Installation is complete once no leaks are detected.

Keywords:

Related Applications

undefined

Language

Language