Products

PRODUCT CENTER

SM39-DH01T HART protocol intelligent temperature transmitter

Category:

1. Overview

SM39 The DH01T HART protocol intelligent temperature transmitter is a high-precision, high-stability, multi-parameter, 4.5-digit LCD display intelligent temperature measurement product that complies with the HART protocol. Users can use the HART communicator to manage, adjust, or monitor process variables of the HART instrument in operation, or use buttons for on-site configuration, which is convenient to operate. With precise digital nonlinear correction technology, safe and reliable explosion-proof structure design and standardized signal output, it features high accuracy and a wide measurement range, suitable for places requiring precise measurement. This product works in a two-wire mode and can directly replace analog two-wire 4~20mADC output transmitters. It can be widely used in various fields such as petroleum, chemical industry, steel, power, building materials, textiles, pharmaceuticals, food, gas, scientific experiments, and military industry. It has been widely used in various oil fields such as Daqing, North China, and Xinjiang, and has won user recognition for its high precision, high reliability, simple installation, convenient maintenance, environmental protection, and durability.

2. Features

·4 ~20mA current output superimposed HART → Protocol digital communication (two-wire);

· Digital nonlinear correction technology is adopted;

· On-site button operation for convenient configuration;

· Protection level IP67.

3. Performance Indicators

Range: -200~650℃ (Customizable);

Accuracy: ±0.5 %FS ( (Customizable)

Operating temperature: -20℃~80℃

Storage temperature: -40℃~85℃

Power supply: (15~30) VDC (Recommended 24VDC)

Digital output: (4~20)mADC output superimposed HART® protocol digital communication

Display: LCD display, two/three-button control

Damping: (0~32)s

Insulation: 100MΩ/50V

O Shaped sealing ring: Fluororubber

Weight: Approximately 1.7kg

Protection level: IP67 ;

Explosion-proof certificate number: CE18.1518 Explosion-proof mark: Exd IIc T4 Gb .

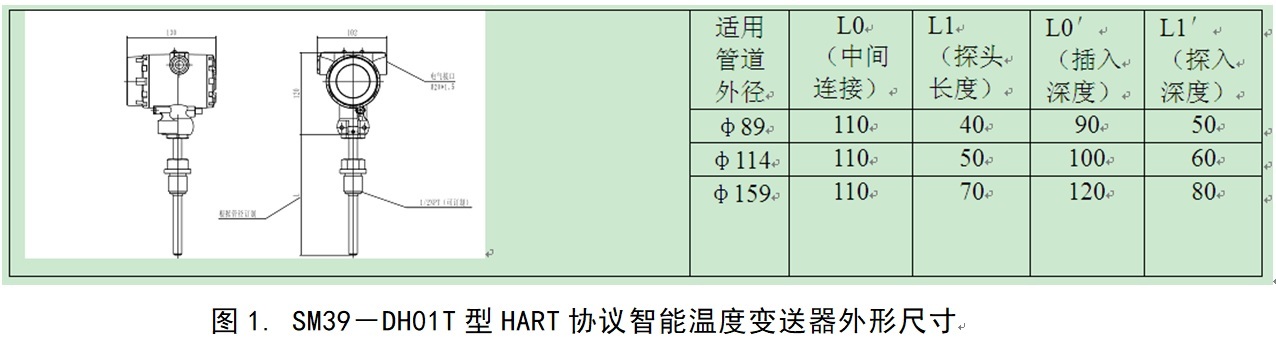

4. External Structure ( Unit: mm )

See diagram for external structure 1,

5. Installation

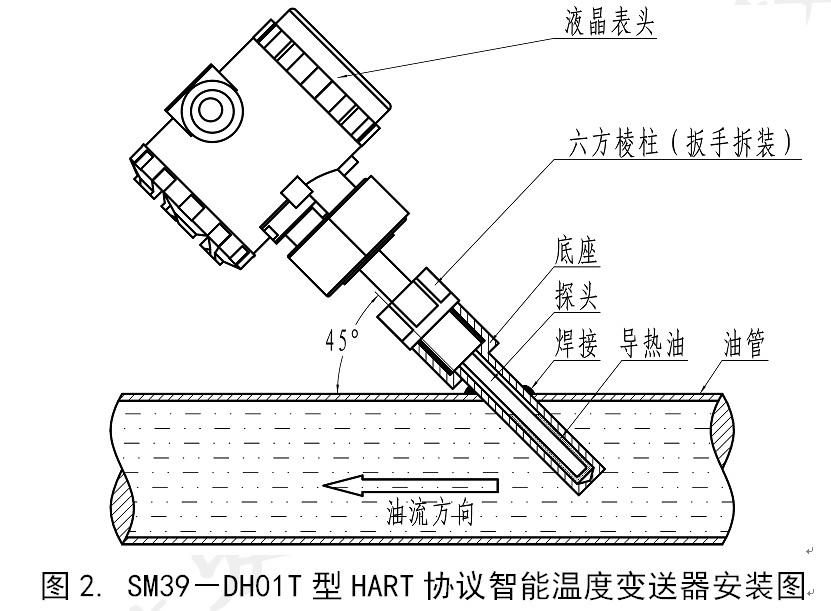

The general installation method is: The sensor probe sleeve is welded to the pipeline (or the device being measured), and the sensor is tightened to the probe sleeve. The following is the installation instructions for the oil pipe of the pumping unit, and other applications are similar.

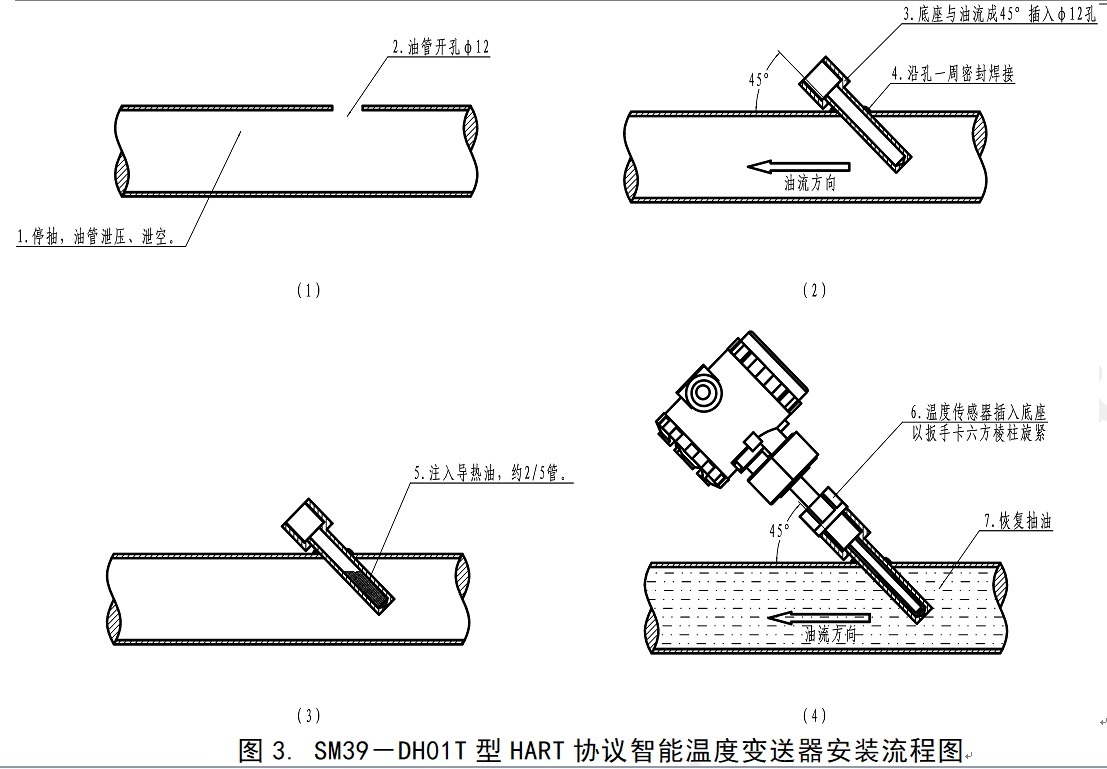

The operating procedure is ( As shown in the figure 2所示):

(1) Close the oil pipe line valve and relieve pressure and air. Drill a hole on the oil pipe slightly larger than the outer diameter of the sensor probe base;

(2) Insert the base from the opening to the maximum depth, adjust the base to a 45° angle with the oil flow, and then seal and weld it to the oil pipe around the hole;

(3) Inject heat transfer oil into the base, about 2/5 of the volume;

(4) Insert the temperature sensor probe into the base, tighten the sensor with a wrench on the hexagonal prism, and open the pipeline valve to restore.

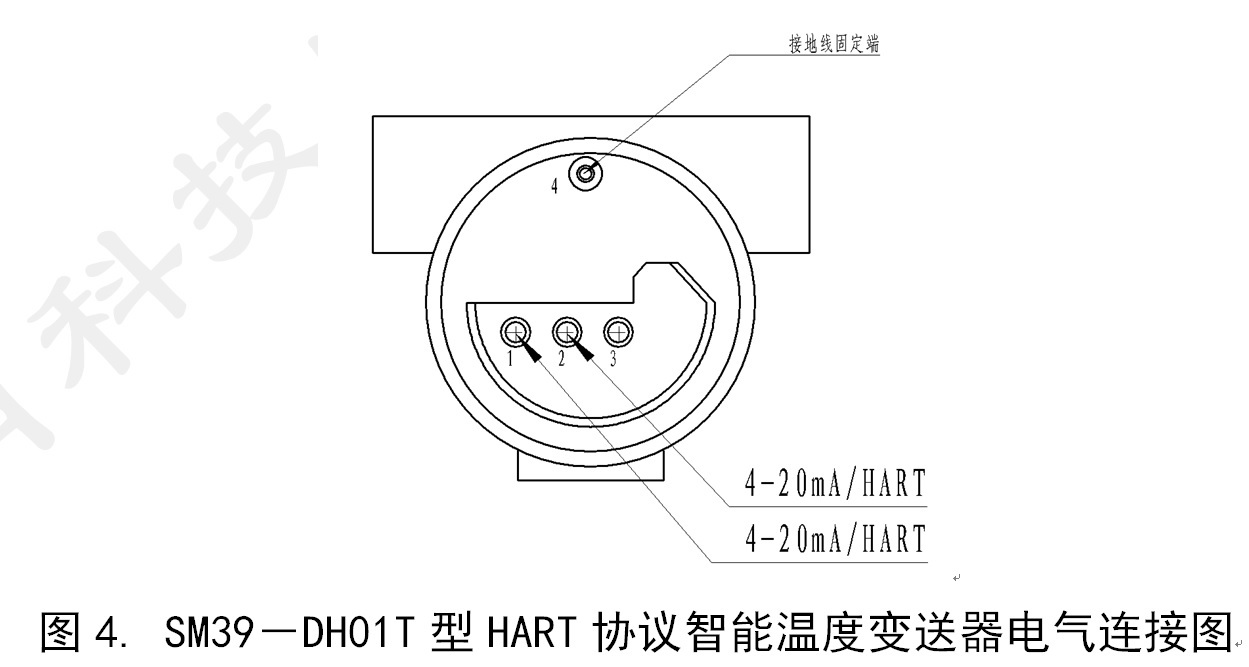

6. Electrical Connection

Open the instrument back cover (wiring terminal), see the wiring terminal, power connection see figure 4 : The left end 1 (Red), 2 (Black) are the sensor power supply and signal wiring, regardless of positive and negative poles, the upper 4 foot is the grounding wire shielding wire fixed end.

7. Precautions

7.1. All sensors have been digitally calibrated, and different sensors have complete consistency and interchangeability.

7.2. Connect the sensor power supply and signal wires to the left end POWER1+(red) and POWER 2-(black) on the three-core terminal, install and tighten the back cover. Be sure to tighten the sheath to prevent water leakage.

Keywords:

Related Applications

undefined

Language

Language