Solutions

Application Solution

Material bin and tank weighing control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

In industrial control sites, real-time monitoring of the actual weight of materials in bins is crucial for controlling various process stages. Our developed weighing control system caters to various equipment involved in raw material storage, conveying, batch weighing, dust removal, material mixing, and packaging and filling, handling diverse substances such as powders, granules, lumps, flakes, liquids, and gases. It ensures scientific management of user production and is custom-designed to meet user process requirements. We provide complete and reliable testing solutions for various industrial sites, with system control interfaces compatible with various upstream and downstream industrial control equipment.

1. System Description

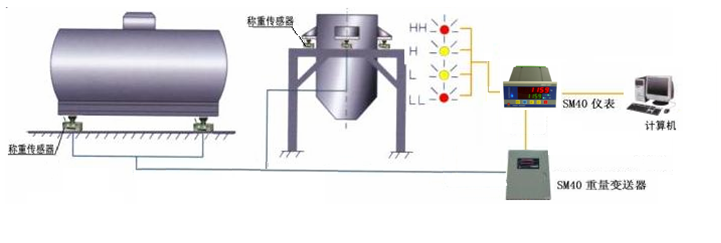

The bin and tank weighing system consists of a weighing bin (user-provided), weighing sensors, and a weighing control box. It is used for weighing solid, liquid, and powdery granular materials in the metallurgical, building materials, pharmaceutical, chemical, and food industries. Riyue Technology Development Group specializes in the R&D and production of high-precision weighing control systems. Its weighing systems are widely used in building materials, chemical, grain, and research fields. The system's high precision and reliability have earned high praise from users. A typical weighing system bin consists of 3-4 sensors. The signals from the sensors are collected and processed in real-time by the backend (wireless module, control instrument, sampling board, etc.). The processed data provides weight display, upper and lower limit alarms, weight signal output, and PID adjustment signal output. It can be easily connected to a DCS system.

2. Functional Features

(1) LCD weight display, LED full-scale (level) ratio, upper upper limit, upper limit, lower limit, lower lower limit alarm display;

(2) Active and passive optional switch input;

(3) OC gate and relay optional switch output;

(4) Optional mA and mV weighing signal input;

(5) Σ-Δ analog-to-digital conversion technology, selectable sampling rate, maximum display scale 60,000d;

(6) With alarm function, alarm threshold can be set;

(7) Calibration data recovery, non-linear correction, automatic zeroing and taring, programmable output signal online, digital filter adjustment;

3. Technical Specifications

(1) Operating power supply: AC 220V ±30%, 50Hz,

(2) Maximum power consumption: 25W, built-in EMI filter

(3) Operating environment: -30~+60℃,

(4) Relative humidity: <90%RH (non-condensing)

(5) Non-linear error: <0.01%

(6) Structural form:

Panel-mounted instrument (SM40-PN), waterproof PE panel, IP65 protection level

Wall-mounted box type (SM40-HN), all-steel sealed, overall IP65 protection level

(7) Input: various strain gauge sensors, input signal 0~30mV;

(8) Output: 0~5VDC, 0~10VDC, 0~10mA, 4~20mA. Optional MODBUS or CANBUS protocol support.

4. Process Flow Diagram

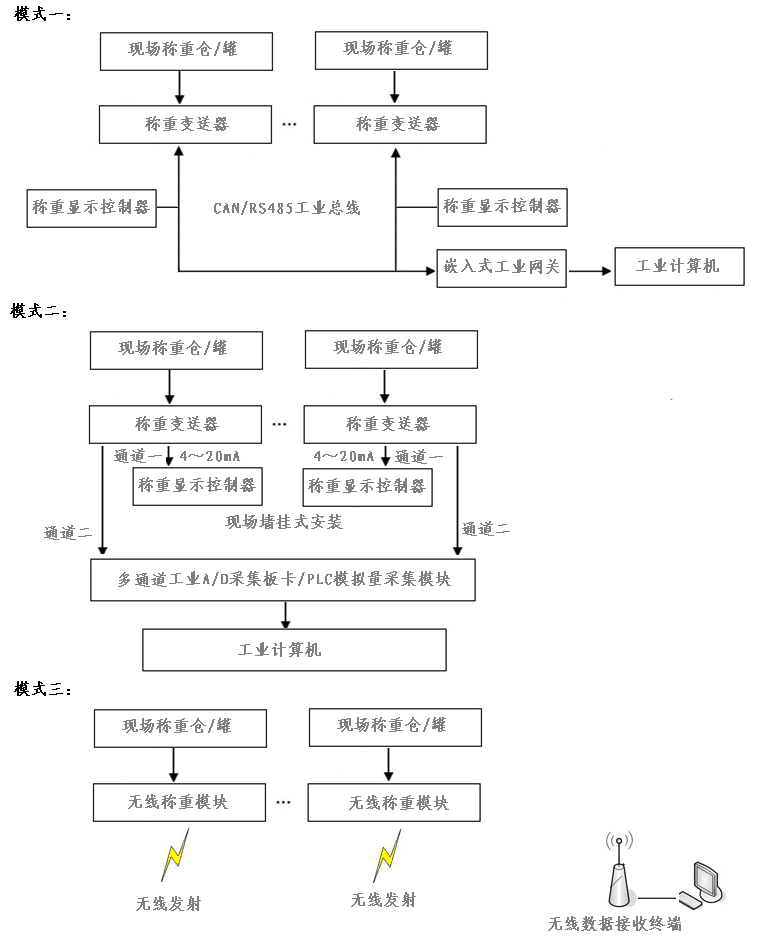

5. Application Topology Diagram

The following diagram shows the application topology diagram designed according to Mode II.

6. Successful Cases

Reactor Weighing Control System

7. Scheme Selection

The bin and tank weighing control system developed by our company can be divided into the following three categories according to the control type:

(1) CAN/485 bus architecture: Industrial control computer, SMTX-CE100 bus gateway, SM40-HX intelligent weighing display controller, field weight transducer

(2) Analog signal acquisition architecture: Industrial control computer, SM40-HX intelligent weighing display controller, industrial analog signal acquisition board

(3) Wireless product architecture: Industrial control computer, wireless weighing transmitter module, wireless connection terminal

Language

Language