Solutions

Application Solution

Application solutions for unattended vehicle scales

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

Electronic weighbridges are the primary weighing equipment used for large-scale cargo measurement in factories, businesses, etc. Before the 1980s, commonly used weighbridges were generally mechanical weighbridges with a purely mechanical structure utilizing lever principles, also known as mechanical weighbridges. In the mid-1980s, with the increasing maturity of high-precision weighing sensor technology, mechanical weighbridges were gradually replaced by electronic weighbridges with high accuracy, good stability, and convenient operation. Ruyue Science and Technology Development Group is a high-tech enterprise in China engaged in the research and development and production of weighing instruments. Based on years of experience, we can provide you with a complete set of solutions for weighbridges and their peripheral control systems.

Keywords: Weighbridge, Digital Weighing Sensor, Junction Box, Display, Software, Digital

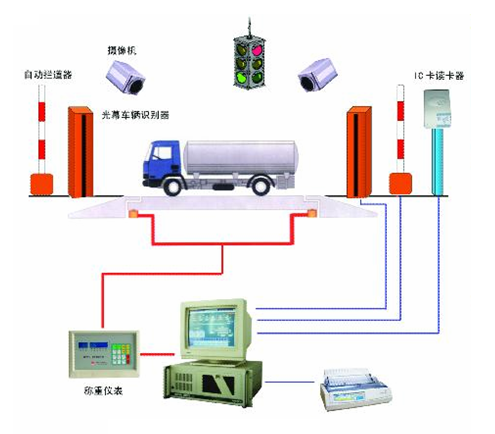

1. System Composition

The SM40 series electronic weighbridge mainly consists of a weighing platform, weighing sensors and connecting components, a junction box, and a weighing display. Its working principle is as follows: The object being weighed or the loaded vehicle is placed on the weighing platform. Under the action of gravity, the gravity is transmitted to the weighing sensor through the platform, causing the elastic body of the weighing sensor to deform. The strain gauge bridge attached to the elastic body becomes unbalanced, outputting an electrical signal that is proportional to the weight value. This signal is amplified by a linear amplifier and then converted into a digital signal by an A/D converter. The microprocessing unit (CPU) of the instrument processes the weight signal and directly displays the weight data. With a printer, weighing data can be printed and recorded. If a computer is configured, the measurement data can be input into the computer management system for comprehensive management.

2. Functional Features

(1) Uses integrated high-precision digital sensors; four-corner error is digitally calibrated; sensors have good interchangeability.

(2) The host computer software embeds Ruyue's self-developed anti-cheating function.

(3) The system has automatic fault diagnosis and error code prompt functions.

(4) Uses an industrial-grade RS485 communication bus; the system has strong anti-interference ability; communication distance is up to 1 km.

(5) Equipped with a lightning protection module; excellent lightning protection capability.

(6) Rich database resources; long-term data storage; weighing slips and reports can be printed; data can be queried; convenient for network management.

(7) The longitudinal bending resistance, transverse torsional resistance, and local compressive stiffness of the weighing platform are greatly enhanced. The weighing platform undergoes strict rust removal and descaling treatment, followed by two coats of high-quality epoxy zinc-rich anti-rust primer. The topcoat is acrylic polyurethane orange peel marine paint, which is wear-resistant, pressure-resistant, and aging-resistant, greatly improving rust prevention performance.

(8) Uses a high-precision weighing display instrument; displays gross weight, net weight, tare weight, and dynamic, underload, and overload statuses.

(9) Has digital filtering, automatic zero tracking, automatic tare, and automatic clear tare.

(10) Supports multiple weighbridges networking; can be connected to the enterprise ERP management system.

3. Technical Indicators

(1) Accuracy Class: OIML

(2) Division Value: ≥3000

(3) Operating Temperature Range: Instrument -10~45℃, Sensor -40~65℃;

(4) Weighbridge Structure: Ultra-high-strength U-shaped steel structure weighbridge

(5) Installation Method: Pitless and shallow pit

(6) Optional Accessories: Computer, printer and weighing management software, large-screen display, voltage regulator or UPS, lightning protection device, barrier gate, electronic camera, card reader, vehicle identifier, traffic light.

4. System Application Diagram

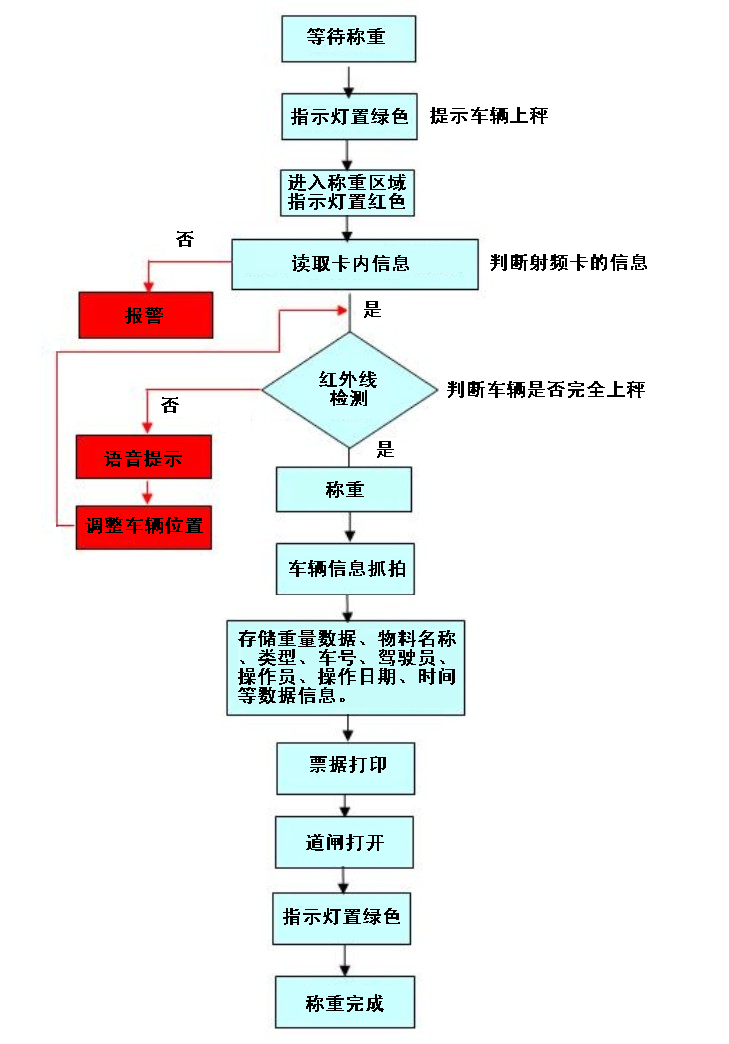

5. System Workflow Diagram

6. Software Function Introduction

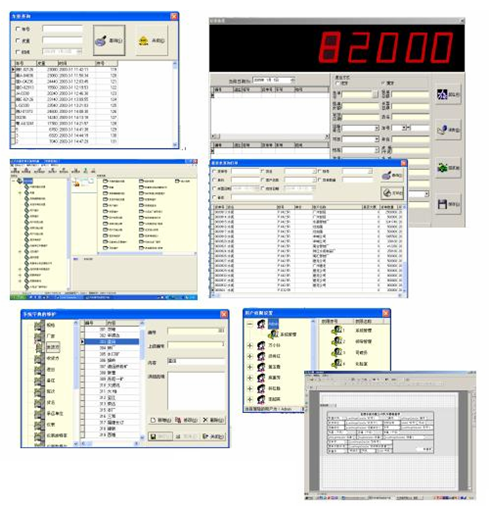

6.1 Single-User Weighbridge Computer Management Software

(1) Suitable for one computer managing one weighbridge. Any weighing instrument with a communication interface, equipped with a computer and this software, can form a single-user weighing management system. The functional features are as follows:

(2) Automatic processing of weighing data. Each weighing records the vehicle number, cargo name, shipping unit, driver, gross weight, net weight, inbound and outbound weighing time, and weigher in the computer; the data is true and reliable.

(3) Weighing results can be queried. Past weighing records can be queried by vehicle number, time range, weigher, cargo type, driver, etc., and can be queried in any combination. It can be queried in a running account manner or in a single card manner. The query work is very simple and convenient, and the computer display is clear at a glance.

(4) Weighing records can be printed. The format of the weighing slip and report can be set.

(5) Weighing data can be backed up; data storage period is long.

(6) Different operation permissions; different content can be operated or queried; responsibility is assigned to individuals; prevents human manipulation.

(7) Instrument communication test function; can adapt to various weighing instruments.

(8) Has multiple query and statistical functions; single or combined queries can be performed on vehicle numbers, cargo receiving and sending units, etc., and various statistical reports can be printed.

(9) The weighing slip format can be designed according to needs to meet the needs of different users.

(10) Supports printing weighing slips in sets to improve printing speed.

6.2 Network Weighbridge Measurement Computer Management System

(1) Suitable for two or more weighbridges operating on a network. In addition to all the functions of the single-user weighbridge weighing management system, the network management system software also has the following characteristics:

(2) Uses an enterprise-level network database system. All weighing data is stored in the same database. Using a client/server model, data is shared among various weighing points, enabling collaborative work. Operators on the network can read the corresponding data according to their permissions.

(2) The gross weight, net weight, or tare weight of a vehicle can be performed on any weighbridge, making measurement work convenient and simple.

Production and scheduling departments can create online scheduling orders or inbound/outbound plans, and weighing personnel can receive work instructions at any time, making the scheduling and management of goods inbound and outbound more convenient.

The finance and production management departments can quickly complete statistical and summary work before the end of the workday. Statistical work is fast and accurate, and financial settlements can be performed at any time without waiting for the weighing personnel to submit weighing statistics.

Company managers can monitor inbound and outbound goods anytime through the network from their offices without needing reports or on-site inspections.

The software also has advanced functions such as license plate management, fraud prevention, and overload detection.

6.3 Vehicle Weighbridge Induction Card System

After the vehicle weighbridge is equipped with a card swiping system, the weighing work can be greatly simplified.

The card stores information such as the vehicle number, unit, driver, number of weighings, and total weight of the weighings. The computer automatically identifies it by swiping the card and can input the required data into the computer at one time for query and various settlements.

Card swiping can make the vehicle weighbridge system unmanned. Before weighing, the driver swipes the card. After the computer receives the card swiping signal, it opens the gate, the vehicle drives onto the scale, and after the data stabilizes, the computer automatically enters the data. After weighing is complete, the front gate opens, allowing the vehicle to leave the weighbridge.

In addition to its features of security, anti-counterfeiting, high capacity, and high reliability, the induction vehicle weighbridge card swiping system is reliable, fast, accurate, long-lasting (with more than 100,000 read/write cycles), and has strong anti-destruction capabilities, making it particularly suitable for public places and group applications.

The card swiping system consists of four parts: a central management unit (central control system, card issuance management system, printer), a card reader, an induction IC card, and a vehicle weighbridge.

7. Successful Cases

Language

Language