Solutions

Application Solution

Stabilized soil plant-mixed equipment control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

With the rapid development of infrastructure construction in China, such as expressways and high-speed railways, the demand for roadbed material production equipment—stabilized soil mixing plants—is increasing. The design of an automatic control system for stabilized soil mixing plants is of great significance in improving the production efficiency and material proportioning accuracy of stabilized soil. This article elaborates on the current domestic and international development status of automatic control systems for stabilized soil mixing plants, combined with the actual engineering needs of the system design object.

Keywords: Stabilized soil, plant mixing equipment

1. System Composition

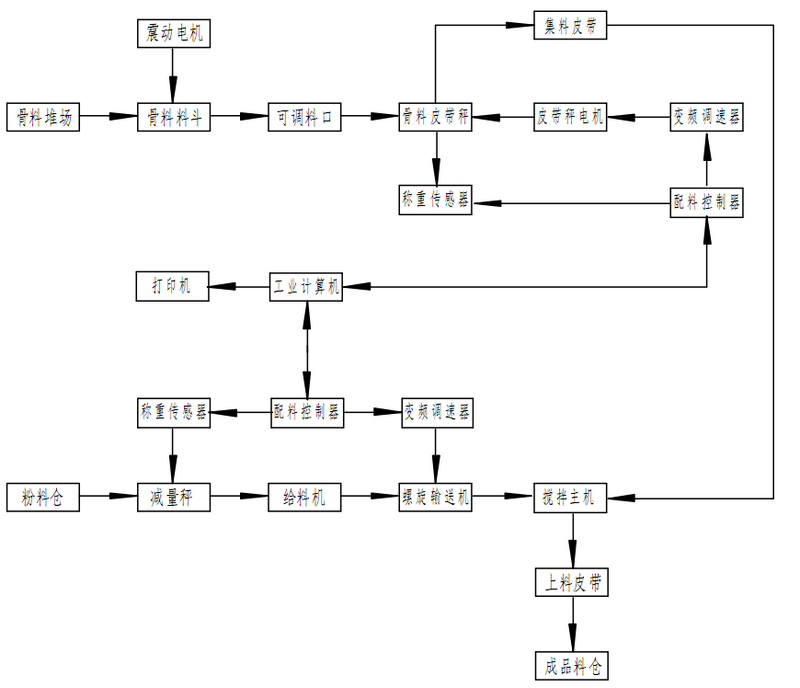

Stabilized soil plant mixing equipment mainly consists of several parts: a computer-based automatic control system, a powder material delivery system, an aggregate delivery system, an aggregate conveyor belt, a mixing device, and a finished product conveying and storage system. There is one set of powder material delivery system and five sets of aggregate delivery systems. In addition, there are water supply systems, air supply equipment, and loading devices.

2. System Overview

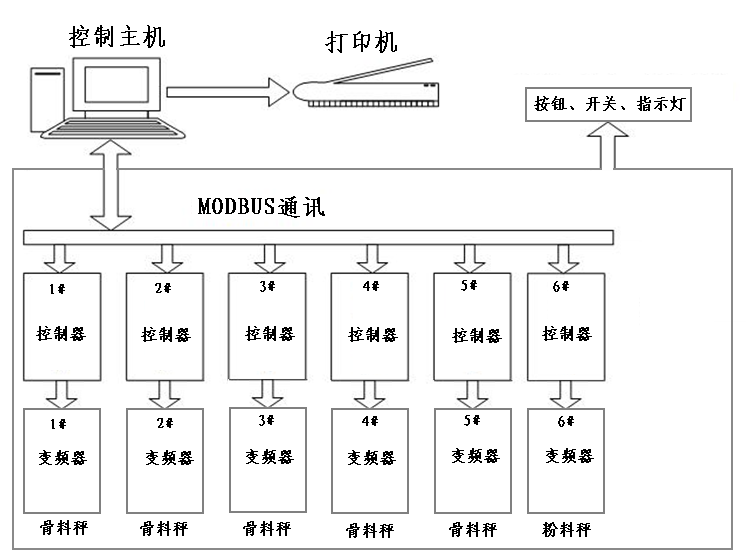

The SMC-2000W series stabilized soil plant automatic batching control system is a new generation of serialized automatic batching control systems developed by the Sun Moon Science and Technology Development Group. This system summarizes years of practical experience in the fields of sensors and dynamic batching, and based on fully digesting and absorbing the technologies of well-known companies at home and abroad, it adopts a high starting point and eclectic approach. It adopts the distributed control scheme in the field of industrial control. The system can realize three levels of control: SM40-CW batching manager (or upper-level industrial computer) centralized management and control → batching instrument independent control → frequency converter direct control, preventing production from being affected by failures in the batching management system. This ensures the stability and reliability of the entire system. Various control devices adopt the RS485 industrial-grade bus communication mode to ensure reliable communication.

3. System Functions and Features

The entire system has full control over automatic batching, continuous mixing, and manual unloading and loading. The system also has manual control functions and on-site safety control. The main batching control schemes are as follows:

(1) Aggregate Batching: It can be composed of 4-6 frequency-controlled conveyor scales, and can be controlled by SM40-2005 or SM40-2000Y conveyor scale controllers to control the frequency converter to adjust the feeding; it can also use volumetric batching controlled directly by the SM40-CW batching manager.

(2) Powder Batching: Continuous loss-in-weight feeders or screw feeders are used for metering, and the control instrument uses the SM40-SG type. The loss-in-weight feeder is a new type of quantitative feeder that uses static metering to achieve dynamic flow measurement, and its metering accuracy is basically close to that of a static feeder.

(3) Water addition control can be realized. The water addition is measured by a flow meter, and adjusted according to the set value.

(4) According to the process flow and equipment layout, the starting sequence and delay time of each batching scale can be selected to ensure that the materials enter the mixer simultaneously, reduce mixing time, and improve mixing efficiency.

(5) The host computer has process flow animation display and parameter modification functions. It has recipe library management, historical data storage, automatic batch reports, daily reports, monthly reports, and annual report statistics and printing functions. The host software has two-level password protection: operation password and important parameter modification password.

(6) The SM40-CW central manager has batching start/stop timing control, scale group definition, recipe management, quantitative management, and miniature printer management.

(7) The central manager implements centralized management and control, the lower-level batching instruments implement independent control, and the frequency converter controllers implement direct control. These three levels of control coexist, preventing production from being affected by batching system failures.

(8) Report printing functions: single batch printing, daily output report printing, cumulative output report printing, and recipe report printing functions.

4. Technical Indicators

(1) Applicable range of the system: 300-600 series stabilized soil mixing systems

(2) Accuracy of the complete system:

Accuracy of aggregates, soil, lime, and fly ash: Closed-loop control is better than 1%, open-loop control is better than 2%, and volumetric control is better than 3%.

Cement metering accuracy: Better than 1%

(3) Instrument and host computer operating power supply: 220V ±15% 50Hz 500W

(4) Ambient temperature: -10~55℃ Relative humidity: <90%RH Non-condensing

5. Network Interface Topology Diagram

6. System Process Flow

7. Scheme Selection

The plant mixing equipment control system developed by our company has three central control methods to choose from:

(1) SMC-2100W High-Performance Stabilized Soil Batching Control Scheme

System configuration: SM40-2000Y LCD conveyor scale controller + industrial computer + needle printer

Control method: Automatic control by industrial computer.

(2) SMC-2200W Medium-to-High-End Stabilized Soil Batching Control Scheme

System configuration: SM40-2005 conveyor scale controller + SM40-CW central manager + miniature Chinese character printer

Control method: Semi-automatic control by central manager.

(3) SMC-2300W Economical Stabilized Soil Batching Control Scheme

System configuration: Manual adjustment of frequency converter + SM40-HC level controller

Control method: Volumetric batching of aggregates, only precise metering control of cement and other powder materials.

Previous:

Language

Language