Solutions

Application Solution

Gas filling control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

【Introduction】

Liquefied gas electronic scale, also known as liquefied gas electronic filling scale (liquefied gas filling machine), is a special equipment used in the liquefied gas industry or large reserve stations. It is generally composed of a filling scale controller, a scale platform, and a solenoid valve. There are also liquefied gas filling scales modified from platform scales. Therefore, the scale can be divided into mechanically modified scales + controllers and fully electronic scales. The explosion-proof electronic filling scale produced by Riyue Technology Development Group is at the leading level in the liquefied gas industry. The scale consists of an advanced filling controller (wired or wireless), a weighing scale platform, and a data processing terminal (wireless base station, computer), equipped with advanced sensors and patented solenoid valves. After years of application in the liquefied gas industry, customers are very satisfied.

1. System Overview

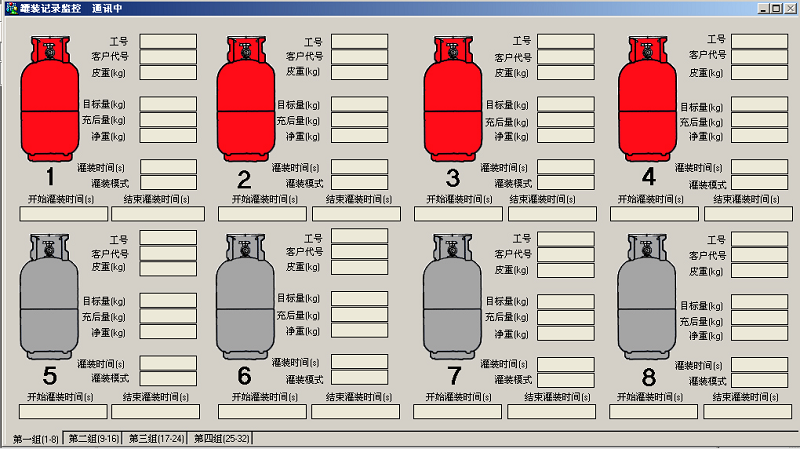

The background computer processing system developed by Riyue Technology Development Group consists of three subsystems: filling scale management system, acquisition system, and billing system. The filling management system mainly monitors the entire system's data, billing records, operator maintenance, and customer information query, deletion, and setting; the acquisition system mainly collects real-time filling records of electronic filling scales, clock correction, and instrument locking; the billing system is mainly used for customer billing. The three subsystems can be installed on the same computer or on different computers within the same local area network. The system defaults to binding the database with the filling scale management system, and the databases of the other two subsystems point to the system's default database. The first time the filling management system runs, it will automatically restore to the local MSSQL database. The computer installing the acquisition system must have at least one serial port.

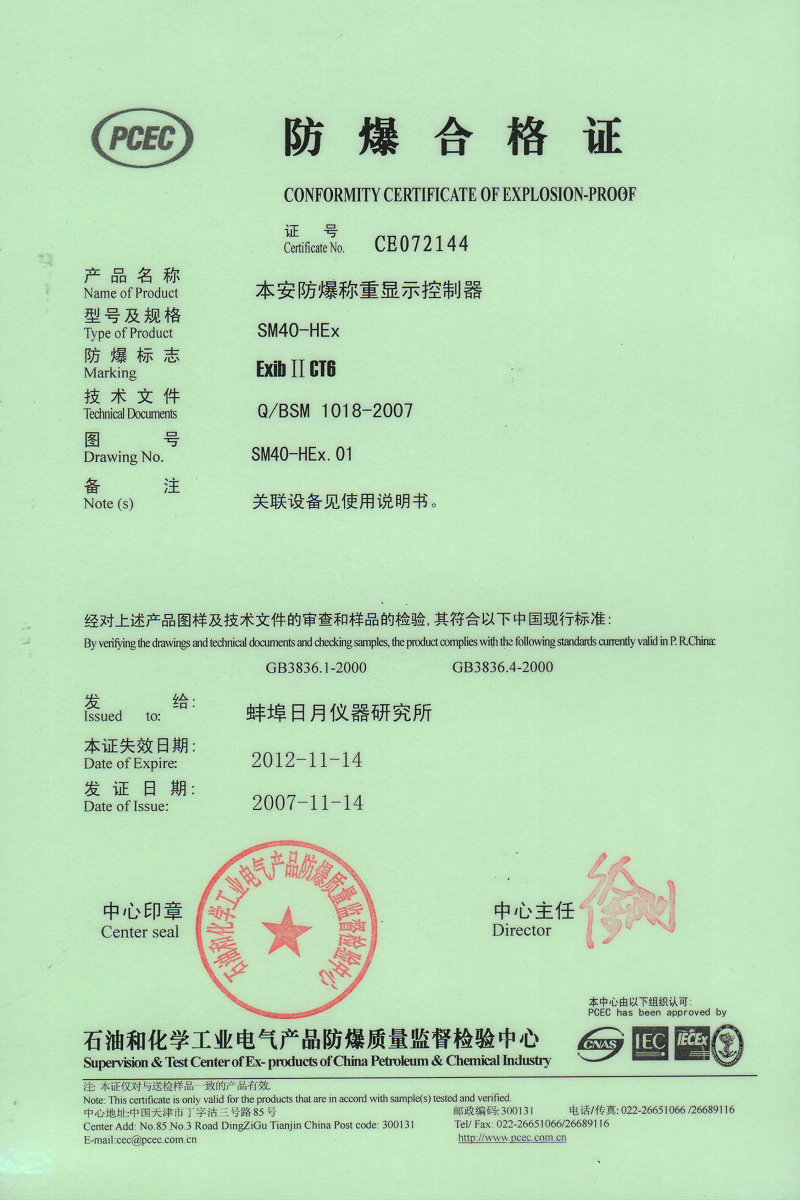

2. Introduction to Explosion-proof Controller

Riyue Technology Development Group is a domestic manufacturer of industrial weighing controllers. Our company develops and produces explosion-proof filling controllers. Explosion-proof mark: Ex ibⅡCT6 Explosion-proof certificate number: CE072144, Implementation standard GB-3836-2000; Metrology license number: Wan Zhe 00000014; Accuracy: Non-automatic scale (Ⅲ), automatic scale (0.5) grade; This system is an industrial intelligent commercial weighing instrument used for automatic filling and batching operations of various types of liquid or solid powder and granular materials. Applicable to Class Ⅱ A~B, T1~T6 group industrial and mining enterprises, weighing and industrial automation control in environments with explosive gas mixtures (alkanes, alkenes, liquefied petroleum gas). It is well-received by users in the fertilizer industry.

3. Functional Features

(1) Automatic tare

(2) Automatic filling control

(3) Automatically remove the weight of the inflation gun and hose

(4) High filling accuracy, the average filling error is almost zero

(5) Sound alarm after filling

(6) Simple and fast filling operation

(7) Easy operation, fast filling speed, one operator can operate 2-3 scales simultaneously

(8) 3 rows of large-size, long-life display screens, clear readings

(9) 20-key membrane control keyboard, greatly improving the operator's control ability

(10) Can record the detailed filling data of each cylinder

(11) Detailed data query and statistics, flexible query and statistical methods

(12) Power-off data saving, ensuring the safety and reliability of statistical data

(13) The upper and lower limits of the empty bottle weight can be set to ensure the safety of filling

(14) Automatically eliminate the influence of the inflation gun weight and hose torque on the filling accuracy

(15) Full-range automatic calibration, only standard weights and buttons are needed to calibrate the electronic scale, which is very convenient

(16) Different permissions can be set according to the different needs of managers to ensure the safety of the filling scale operation

(17) It has shockproof and impact-resistant functions and anti-electromagnetic interference functions

(18) Intelligent management and operation functions for filling operations

(19) Can be connected to a computer network to monitor the filling management system (needs to be purchased separately)

(20) Wired and wireless transmission methods can be selected

4. Technical Indicators

(1) Accuracy: Class III

(2) Division value: 50g

(3) Range: 120kg

(4) Display: Three display windows, 12-digit 0.8-inch LED, 6-digit 0.5-inch LED, 9 status indicator lights

(5) Keyboard: 20 touch keyboards

(6) Communication: Both wireless and wired communication

(7) Operating power supply: 12VDC (-25% - +25%)

(7) Operating temperature: -10 ~ +40℃

(9) Operating humidity: <90%RH (no condensation)

(10) Rated power: 3.6W

5. On-site filling pictures

6. Software Function Introduction

System functions:

(1) System settings: Change the name of the liquefied gas station, add the inventory of liquefied gas;

(2) Scale group setting is to select the machine number of the corresponding electronic filling scale as the object called by the communication base station; a base station can call up to 32 electronic filling scales in a round-robin manner;

(3) Customer information maintenance is to set the basic information of the customer, and customer configuration is the product name, unit price, and customer type purchased by this customer. After setting the basic information of the customer, you must configure the customer, otherwise the billing system will not allow billing;

(4) Customer configuration is the setting of the customer code, the product name to be purchased, and the unit price for this customer. When billing, you do not need to enter the unit price after selecting the customer code;

(5) Permission function settings allow system administrators to set permissions for operators or administrators. After adding a new operator, the permissions for accessing and operating within these three systems using their username and password are set here. Unselected permissions will be unavailable to the operator after logging in.

(6) Operator maintenance involves setting up basic information for operators, such as employee ID, name, phone number, and password.

(7) User-defined common data. The number of digits in the serial number refers to the number of digits in the serial number when issuing invoices: current date + serial number digits.

(8) Filling record query allows searching for records within a specified time range based on machine number, employee ID, customer code, filling mode, target quantity, etc.

(9) Monthly report query provides monthly statistics of system invoicing records. Select the year, month, and product name, and click "Query" to view the total monthly statistics generated by system invoicing for the corresponding month.

(10) Invoice query allows searching for operator invoicing records based on time range, unit price, customer code, and serial number.

(11) Data deletion allows deleting filling records within a specified start and end time range.

7. Explosion-proof product qualifications

Language

Language