Solutions

Application Solution

Concrete mixing control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

Concrete mixing plants have become the main site for concrete production. The weighing and batching process, as a key link in the concrete production process, is an important factor affecting the quality of concrete. At the same time, the performance of the control system is very important for the normal operation of the mixing plant. First, the quality of the control scheme determines whether the mixing plant can operate stably and reliably; second, the choice of control strategy determines the production efficiency and batching accuracy of the mixing plant; third, the design of the host computer monitoring software determines the ease of use and convenience of human-computer interaction. This article will elaborate on each of these points.

Keywords: Concrete mixing plant, Batching accuracy, Host computer, Monitoring software

System Composition

A concrete mixing plant mainly consists of five major systems: a mixing host, a material weighing system, a material conveying system, a material storage system, and a control system, as well as other auxiliary facilities. The SM8000 series fully automatic concrete batching control system is a new generation of automatic control system developed by our group for various types of mixing plants (buildings) at home and abroad. It uses the SM40-CG-CAN batching manager (CANBUS bus) as its core, creating a unique and novel working mode of "batching controller (independent batching control) + batching manager (comprehensive electrical timing control management) + host computer network management (host computer network database management system)". It has high reliability and long-term stability; it realizes decentralized control and centralized management. It has management functions that cannot be achieved by PLCs used in previous small and medium-sized batching control systems.

System Overview

Concrete is made by mixing aggregates (sand, stone), cement, water, admixtures, and admixtures in a certain proportion. It is one of the most widely used materials in construction engineering, and its economic and technical indicators are crucial to the quality and cost of the entire construction project. In order to improve the strength of concrete, save cement, and meet certain technical requirements, various raw materials must be strictly matched according to pre-tested proportions. Early concrete was mainly produced by construction sites themselves. This method has low production efficiency, high labor intensity, serious noise and dust pollution, and large quality fluctuations. With the development of China's economic construction, the start of construction of a series of infrastructure projects and the acceleration of urbanization, the demand for concrete is increasing, and the requirements for its quality are also increasing. Traditional production methods can no longer meet the needs of construction, and with policy guidance, in recent years, factories specializing in the production of concrete—commercial concrete mixing plants—have developed rapidly. A concrete mixing plant is a complete set of equipment that measures various materials that make up concrete according to the proportion requirements, and then mixes them into qualified concrete by a mixer. It has the characteristics of high degree of automation, high production efficiency, and low environmental pollution. The quality of the concrete products produced is excellent and stable, and the production cost is low. Therefore, it has been rapidly developed and promoted in large and medium-sized cities across the country, becoming the mainstream of concrete production.

System Functional Characteristics

The main controller of the SM8000 system, the SM40-CG-CAN batching manager (CANBUS bus), is a device developed by the R&D Group of Riyue Technology Development Group based on many years of practical experience in mixing plants. It integrates PLC control functions, formula management, comprehensive printing and statistical management, and password restrictions. Compared with traditional systems, it has the following advantages:

(1) Modular design, strong redundancy: Each material is independently controlled for batching → manager comprehensive batching control → host computer batching monitoring management → seamless upgrade of network computer management, realizing decentralized control and centralized management.

(2) Industrial fieldbus or RS485 communication is used; the SM40 series batching controller uses a sampling rate of 200 times/second and independent switch material gate control. Compared with traditional systems, the batching is faster, more stable, and more reliable, and the batching process can fully meet the process requirements of any mixing plant (building).

(3) The main controller uses a Chinese character LCD display, with an industrial-grade embedded microprocessor as its core. It is designed according to ultra-industrial standards, with a wide voltage of 85V~265VAC power supply, a full-metal industrial-grade structure, wide temperature range, anti-electrical interference, and lightning protection, meeting the requirements of various harsh environments.

(4) It can connect to 1~6 batching instruments through the communication port. The batching instruments are defined as: aggregate meter, cement meter, admixture meter, water meter, extended aggregate meter, and extended powder meter. Each meter can be equipped with four materials, fully meeting the requirements of commercial concrete mixing plants.

(5) The main control instructions and timing are solidified in the batching manager, which can prevent the out-of-control phenomenon that occurs when the host computer crashes.

(6) Lightning protection and anti-EMI interference design measures ensure reliable lightning protection and anti-interference capabilities of this control system.

(7) Abandoning PLC, low price, high performance.

Technical Indicators

(1) Power supply: System: 380 VAC±10% Instrument: 220 VAC±30% Host computer: 220 VAC±10%

(2) Relative humidity: System: ≤90%RH (no condensation)

(3) Ambient temperature: System, instrument: -35~65℃ Host computer: 0~50℃

Control Software Description

(1) Software functions

The commercial concrete network management system takes "collaborative business, centralized management" as its core application concept, and takes the production and sales of commercial concrete as its main line. It is a complete set of management application software for the commercial concrete industry.

While fully realizing the procurement, production, quality inspection, transportation scheduling, warehouse management, signing, and settlement management of concrete raw materials, it focuses on the control of production management and sales processes, such as contract management, accounts receivable management, and concrete production records.

For many special requirements of the concrete industry, the system provides unique processing methods, such as signing/cross-household processing, project settlement management, 24-hour overnight delivery, and reverse deduction of raw material consumption based on formulas.

(2) Software architecture

This product mainly includes modules such as sales contracts, demand records, production management, mix ratio management, production records, transportation scheduling, warehouse management, equipment management, weighing management, quality inspection management, purchase contracts, purchase management, and system management. Each module is seamlessly connected.

(3) Software features

Utilizing SQL Server 2000 enterprise-level database, the backend data is dynamically maintained, with customizable backup methods and timeframes. The system enhances data platform automatic maintenance and concurrent control through a dynamic locking mechanism. Detailed permission settings and role management functionalities allow assigning permissions to operators. Operational logs record every network action for traceability, ensuring correct system operation and data security. The system offers extensive data import and export capabilities; account data can be directly generated as browser-supported HTML files for publication on the internet/intranet. All data is stored on the server, enhancing security through data concealment. The database itself is appropriately encrypted, preventing unauthorized access or modification of business data by third-party tools without system administrator credentials.

(4) Reporting Functions

Print and query daily, monthly, quarterly, and annual production reports.

Print and query production reports for each formula.

Print and query comparative reports of theoretical and actual consumption for each material.

Print and query comparative reports of theoretical and actual consumption for each formula.

Print and query detailed ingredient reports for each production batch.

Print and query detailed and summary reports of transportation vehicle shipments.

Print and query detailed and summary reports of customer material usage.

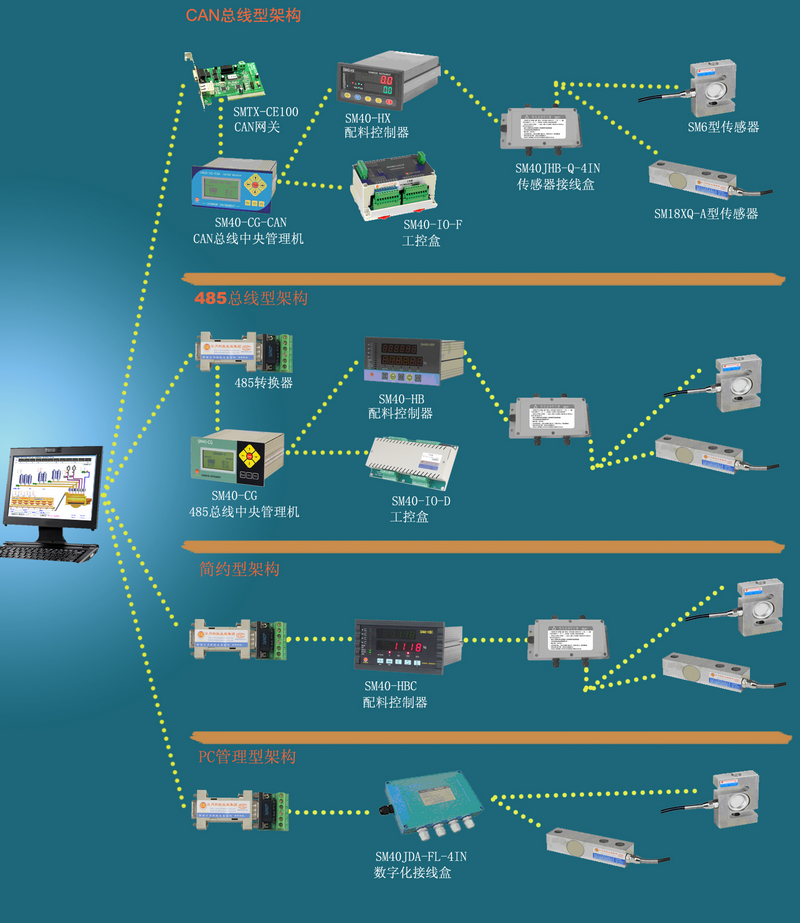

6. Network Interface Topology Diagram

The following diagram illustrates four different configurations: CAN bus architecture, 485 bus architecture, simplified architecture, and PC management architecture.

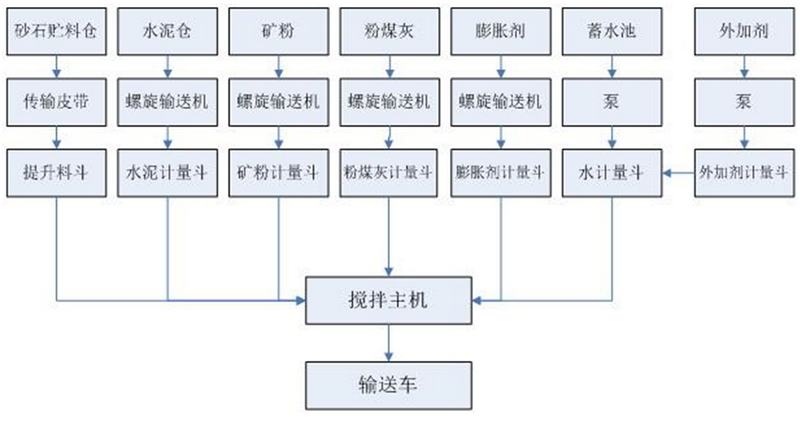

7. System Process Flow

The raw materials for producing concrete generally include coarse aggregate (stone), fine aggregate (sand), cement, admixture (fly ash), water, and admixtures. Various raw materials are weighed and batched according to a given ratio (formula), then unloaded into a mixer for mixing. After mixing for a given time, wet finished concrete is formed and can be delivered to the construction site. The production process is shown in the diagram below:

8. Scheme Selection

The concrete mixing plant control system developed by our company can be divided into the following four categories according to control type:

(1) CAN bus architecture: SMTX-CE100 bus gateway, SM40-CG-CAN bus manager, SM40-HX bus batching controller, SM40-I/O-F bus controller

(2) 485 bus architecture: SM40-485 communication converter, SM40-CG central manager, SM40-HBC batching controller, SM40-I/O-D industrial control box

(3) Simplified architecture: SM40-485 communication converter, SM40-HBC batching controller

(4) PC management architecture: SM40-485 communication converter, SM40JDA digital junction box

Language

Language