Solutions

Application Solution

Track ballast full-performance test solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

Sleepers, also known as ties, are a type of railway accessory. However, the materials used are no longer limited to wood, so the term "sleeper" is more scientifically accurate. Although sleepers may appear monotonous and unremarkable, their role is significant. Sleepers support the rails, maintain their position, and transfer the immense pressure from the rails to the ballast. They must possess a certain degree of flexibility and elasticity; neither too hard nor too soft. When a train passes, they can deform slightly to cushion the pressure, but they must return to their original state as much as possible after the train has passed. The sleeper full-performance testing system developed by Riyue Technology employs new technologies such as high-precision load sensors, microcomputer control, and electro-hydraulic proportional hydraulic loading systems. It can accurately and quickly detect the static load strength of various sleepers and test their actual load-bearing capacity. Static load points can be arbitrarily set, and data result reports are automatically printed. The sleeper static load testing machine mainly consists of a press, trolley, track, lifting mechanism, hydraulic system, and electrical control system.

Keywords: Sleeper, Sensor, Microcomputer, Hydraulic

Application Range

Suitable for testing the static load tensile strength of concrete sleepers (Type Ⅰ, Type Ⅱ, Type Ⅲ, fork sleepers, bridge sleepers, wide sleepers, etc.)

System Composition

It adopts digital bus technology, microcomputer program control, and servo hydraulic loading system, etc. It can accurately and quickly detect the static load strength of various sleepers and test their actual load-bearing capacity. The sleeper static load testing machine mainly consists of a press, trolley, track, lifting mechanism, hydraulic system, and electrical control system. It fully meets the technical conditions of the concrete sleeper static load testing machine formulated by the China Academy of Railway Sciences.

Standard Configuration

1. Piano-style operating table

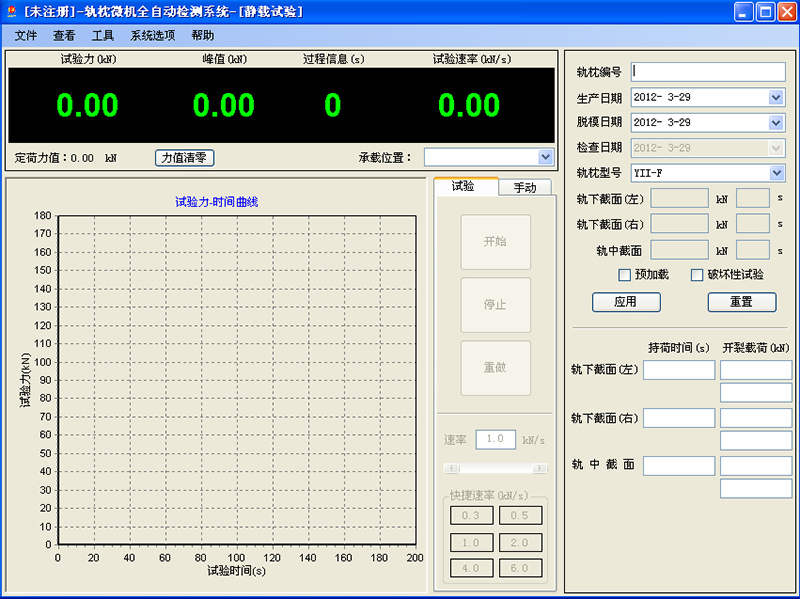

SM800 host computer control software

Advantech IPC610H (or Siemens IPC547C) industrial control computer

SM40-CJ high-precision data acquisition system

DELL E190S widescreen LCD monitor

Epson EPSON dot matrix printer

Schneider Electric (Siemens) electrical components

2. Weighing module: SM series various types of weighing sensor modules

Functional Characteristics

1. High-precision sensor, modular design

2. High-precision multi-channel data acquisition and control system

3. Servo driver drive, high precision, good reliability

4. The software adopts a standard Windows interface style, which is simple, intuitive, easy to operate, and easy to master.

5. Software calibration function, calibration data has query, save, and restore functions.

6. Rich parameter setting functions, PID parameters can be set.

7. Under-rail load retention, under-rail loading, mid-rail load retention, mid-rail loading, loading rate, and ringing delay parameters can be set.

8. The test detection completion mark has single-sided cracks and double-sided cracks to choose from.

9. Preload setting function

10. Automatic adjustment of the test coordinate axis

11. Peak hold function, constant load timely function

12. Real-time display of test loading rate function

13. Manual and automatic test functions

14. Quick loading method rolling adjustment function

15. Real-time acquisition and display of force value, supporting multiple test control methods, and able to meet the test needs of different users.

16. Records the test force-time curve, which can be switched and observed at any time, zoomed in and out arbitrarily, and moved in any direction.

17. Test data is managed using a database, automatically saving all test data and supporting multi-condition data query methods.

Technical Indicators

1. Maximum under-rail load: 500KN

2. Load indication accuracy: ±1%

3. Initial load after placing the sleeper: <20KN

4. Loading speed: 3000±300(N/S)

5. Load retention time: 180S

6. Maximum piston stroke: 250mm

7. Adjustable under-rail loading distance: 600, 700, 800 (mm)

8. Adjustable mid-rail loading distance: 600, 1500 (mm)

9. Test Space

Distance between upper and lower supports: 430mm

Distance between four columns: 900, 900 (mm)

10. External Dimensions

Main unit: 1720﹡1060﹡2266 (mm)

Trolley: 3390﹡700﹡135 (mm)

Control cabinet: 700﹡770﹡1110 (mm)

11. Hydraulic pump station related parameters

Rated pressure: High-pressure oil pump 16Mpa

Rated displacement: High-pressure oil pump 5ml/rec

Motor power: 1.1KW, speed 1800rpm

Language

Language