Solutions

Application Solution

Plaster equipment control system solution

Category:

Weighing solutions

Publish Time:

2020-07-09

Abstract

Plaster, as a traditional Chinese medicine preparation, has a long history, but for a long time, the production process has mostly used high-temperature decoction and manual spreading with heat preservation. Due to its high viscosity, manual operation is very inefficient, making it difficult to achieve the dosage requirements specified in the pharmacopoeia, which is incompatible with the development of current pharmaceutical technology and makes mass production difficult. Therefore, we have developed an automatic plaster machine that uses constant temperature and constant pressure. The medicine weight is controlled by a high-precision weighing display controller, effectively solving the problems of difficult-to-master dosage control and low work efficiency in plaster making, and has certain versatility for producing plasters with different matrices and different dosage requirements.

Keywords: Plaster machine, high-precision weighing, small dosage

1. System Description

Currently available plaster machines are basically divided into two categories: one is a machine modified from adhesive tape equipment to make plaster. Its purpose is to apply the plaster relatively evenly to non-woven fabric, and then cut it. The production process cannot control the weight of a single piece, but it has the advantage of continuous production and is suitable for mass production. The SM40 small-range high-precision weighing control system developed by Riyue Science and Technology Development Group can not only greatly improve production efficiency, but also its control accuracy fully meets the explicit provisions in the pharmacopoeia, that is: the tolerance for plaster weight testing standards is ±10% for 0.1g~3.0g, ±7% for 3.0g~12g, ±6% for 12g~30g, and ±5% for >30g.

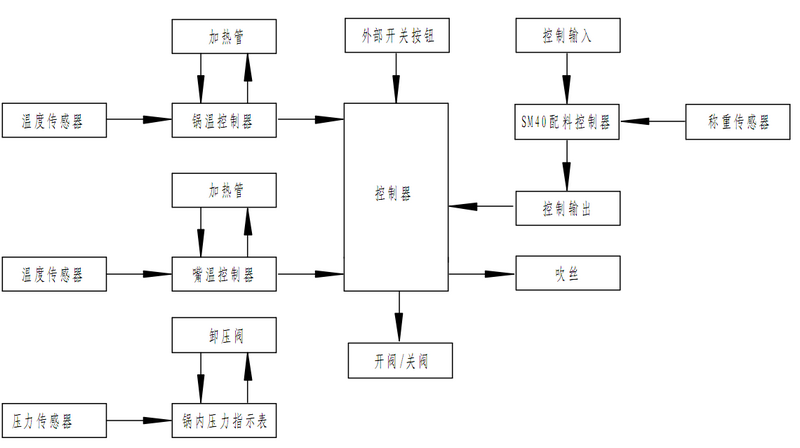

2. System Structure and Working Principle

A conventional plaster machine consists of a medicine barrel, an electric heater, a small air compressor, a medicine dispensing control valve, a temperature control circuit, a high-precision weighing display controller, and pneumatic molding control. The advantage of the automatic plaster machine is that it solves the problems of quantitative spreading and automatic plaster shaping in production. To ensure accurate dosage, the machine uses a constant temperature method, with a temperature controller controlling the temperature of the electric heating medicine barrel and adjusting its temperature value as needed, with an adjustable range from room temperature to 100℃. Only under the condition of stable temperature parameters can the dispensing amount be basically consistent within the same time. Therefore, a high-precision weighing sensor is designed to achieve the purpose of controlling the dosage by means of real-time high-precision weighing control.

This plaster machine uses a high-precision weighing display controller as its core. The SM40 high-precision weighing display controller developed by Riyue Science and Technology Development Group has high precision and high system reliability. Its input part (batching start) can be connected to an external foot pedal control signal or a photoelectric sensor signal. The control output part consists of a control circuit and mechanical parts. The controller outputs valve opening, valve closing, and air blowing signals. The control motor is a gear reduction DC motor, and the control motor is connected to the dispensing nozzle ball valve shaft below through the valve, and the ball valve rotates with the motor. Two limit switches control the angle to 90 degrees to complete the opening or closing of the ball valve. When the weighing is completed, the controller outputs an air blowing signal to break the plaster thread.

3. System Controller Features

(1) Anti-electromagnetic interference, low electromagnetic leakage radiation, impact resistance, corrosion resistance

(2) Waterproof, dustproof, easy to clean

(3) Digital filtering function for dynamic weighing, enhancing the stability and anti-interference ability of weighing

(4) Dual display can cyclically display gross weight, net weight, tare weight, and batching operation status information

(5) Drop automatic correction or non-correction selection

(6) Software digital calibration function, simplifying calibration work

(7) 10 relay control output points, each interface has a maximum load capacity of 60VDC/0.5A

(8) Powered by a high-performance encapsulated power supply module to meet the requirements of a wide voltage range

(9) Uses advanced SMT technology sampling chip, faster sampling speed

(10) Recipe setting and adjustment function.

4. Control System Technical Indicators

(1) Plaster weight: 0.02g~200.00g

(2) Control accuracy: 0.01g

(3) Applicable sensor type: Applicable to all strain gauge type force and weighing sensors

(4) Sensor supply voltage: DC 10V, can connect 8 350-ohm sensors in parallel

(5) Input sensitivity: From 0.5 microvolts to 400 microvolts per grid

(6) Input impedance: >10MΩ

(7) Full-scale temperature coefficient: <5ppm/℃

(8) Nonlinear error: <0.01% full scale

(9) Sampling method: ∑-△ signal analog-to-digital conversion and high-speed signal processing technology

(10) Sampling speed: 300 times/second

(11) Internal resolution: 1/1,000,000, visible resolution is 1/260,000

(12) Display scale: From 0~200,000 divisions

5. Control Part Interface Circuit

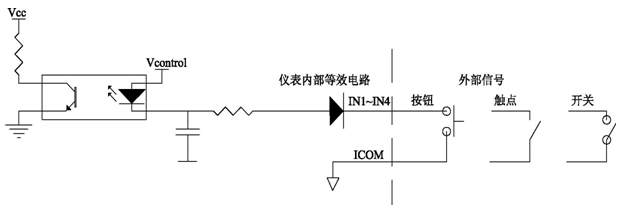

5.1 Control Input Interface Circuit

The control input interface receives external start signals to start the batching operation.

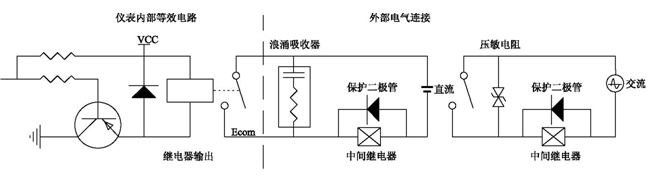

5.2 Control Output Interface Circuit

The control output interface receives control signals to open the batching door, blow the thread, and close the batching door.

6. System Process Flow

Language

Language